PERIODIC MAINTENANCE

EAS21030

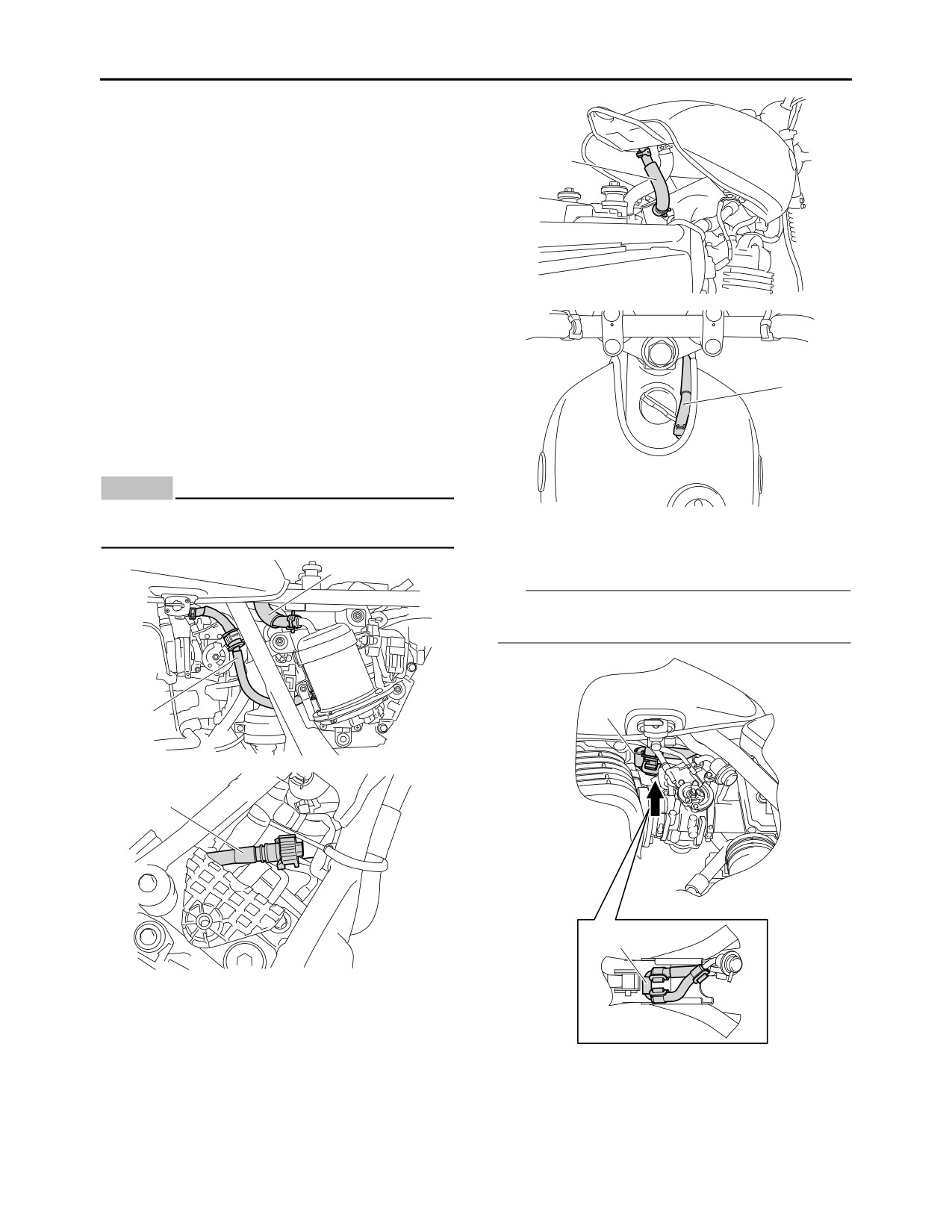

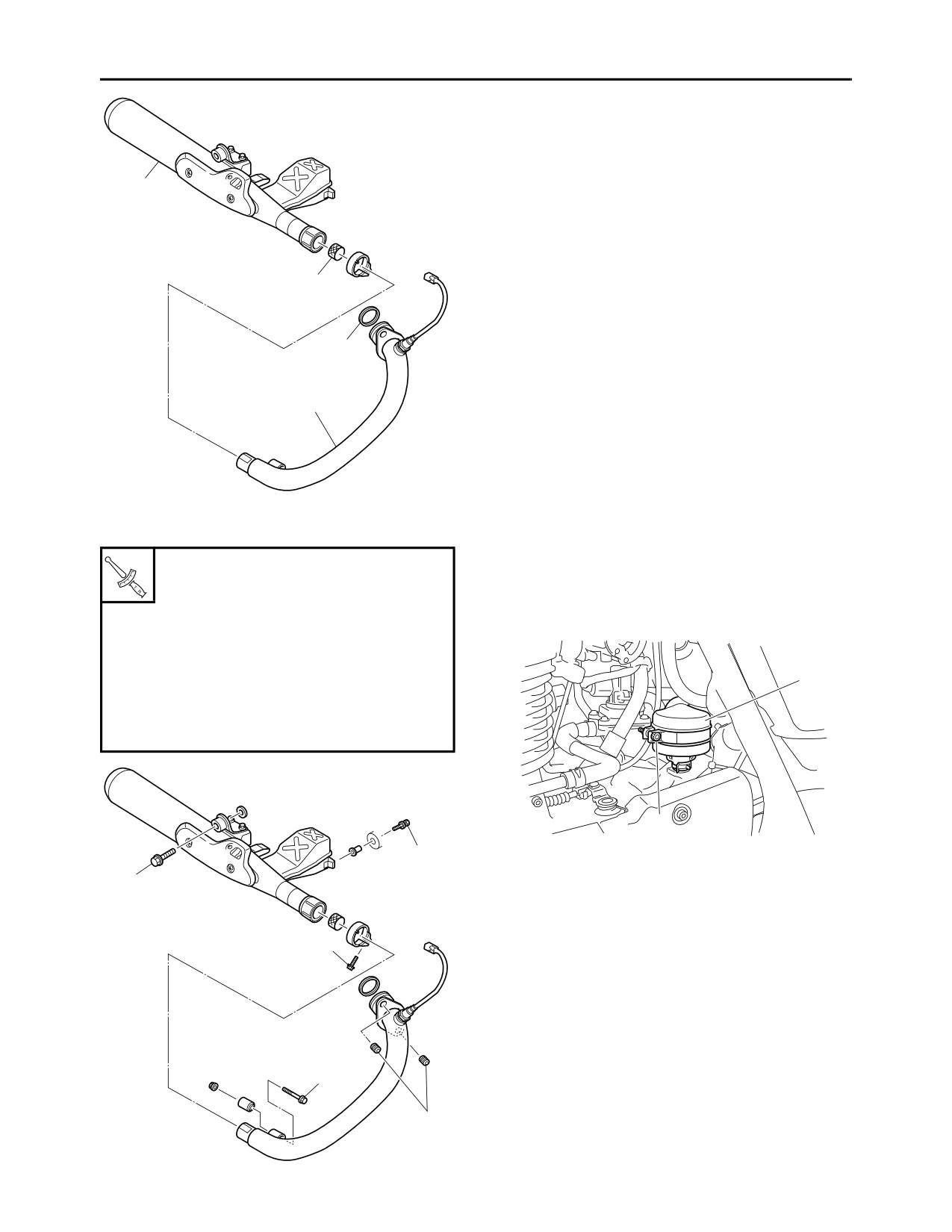

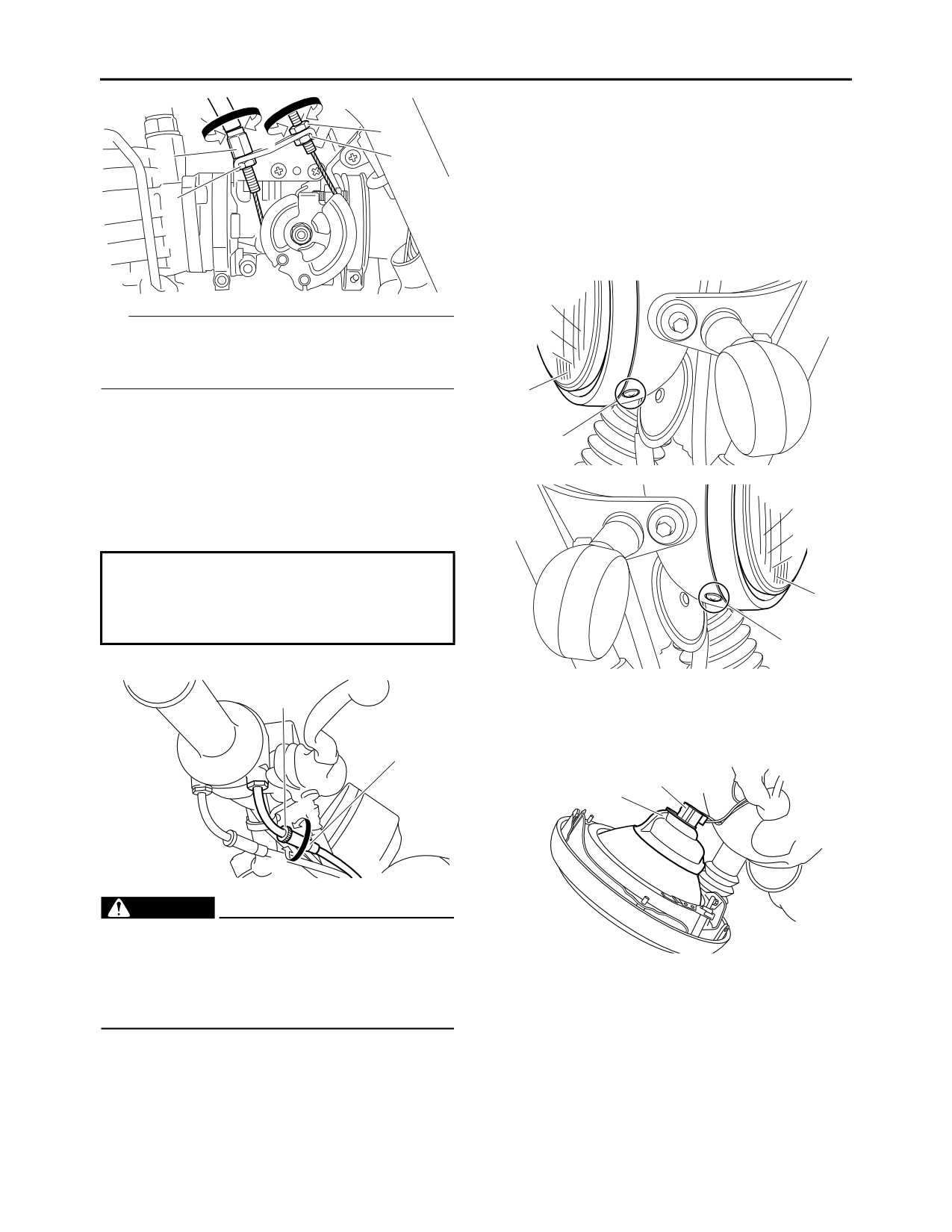

CHECKING THE FUEL LINE

The following procedure applies to all of the fuel,

vacuum and breather hoses.

4

1. Remove:

• Seat

• Side cover (left)

Refer to “GENERAL CHASSIS” on page 4-1.

• Fuel tank

Refer to “FUEL TANK” on page 6-1.

2. Check:

• Fuel hose (fuel tank-fuel pump case) “1”

• Pump case breather hose (fuel pump case-

fuel tank) “2”

• Fuel hose (fuel pump-fuel rail) “3”

5

• Fuel hose (pressure regulator-fuel tank) “4”

• Fuel tank breather hose “5”

Cracks/damage Replace.

Loose connections Connect properly.

ECA14940

NOTICE

Make sure the fuel tank breather hose is rout-

3. Check:

ed correctly.

• Fuel hose (pressure regulator-fuel tank) lo-

cation

2

TIP

Make sure that the fuel hose “1” is located (be-

low the frame), as shown.

1

1

3

1

4. Install:

• Fuel tank

Refer to “FUEL TANK” on page 6-1.

• Side cover (left)

• Seat

3-4

PERIODIC MAINTENANCE

Refer to “GENERAL CHASSIS” on page 4-1.

plug and gasket surface.

EAS20690

8. Connect:

CHECKING THE SPARK PLUG

• Spark plug cap

1. Remove:

EAS20520

• Spark plug cap

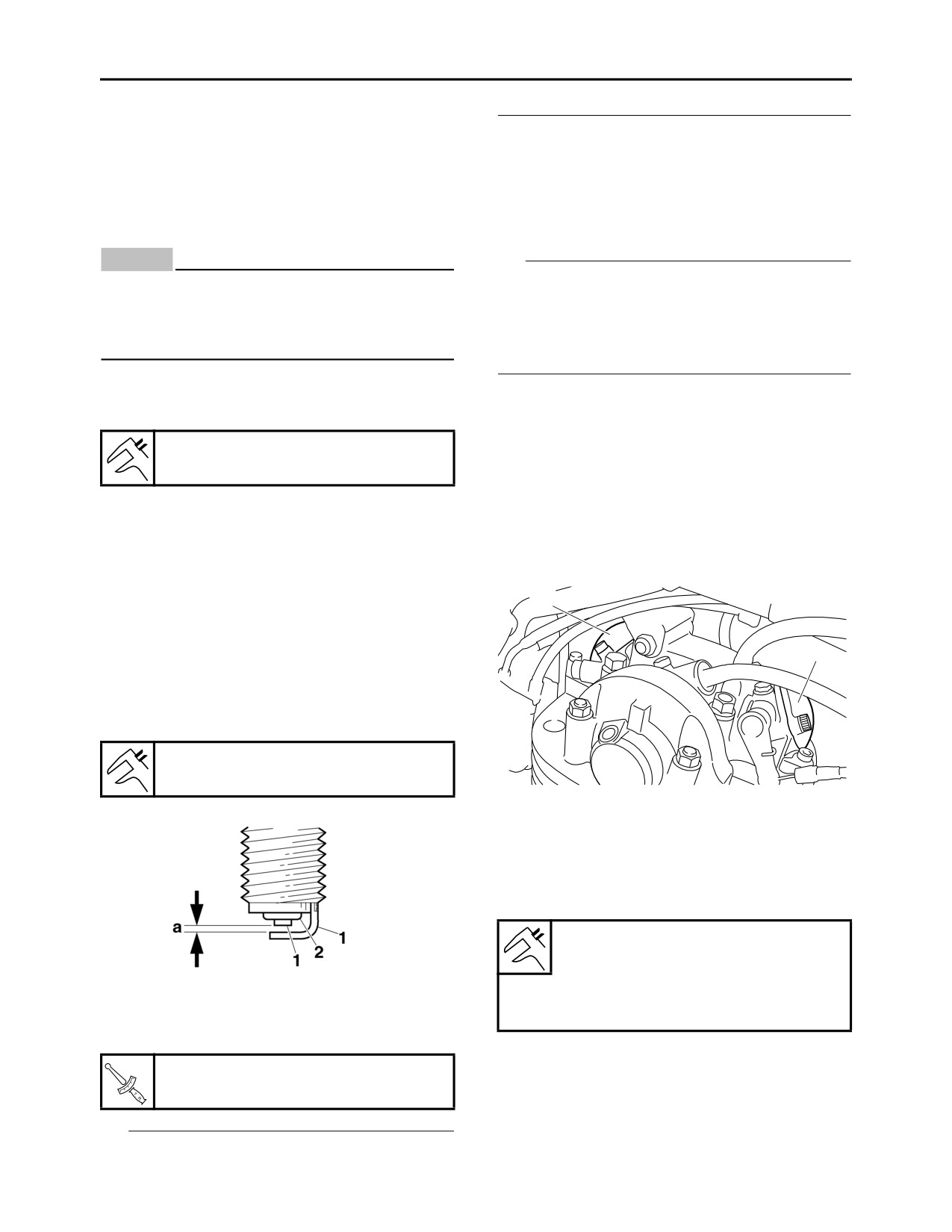

ADJUSTING THE VALVE CLEARANCE

2. Remove:

The following procedure applies to all of the

• Spark plug

valves.

ECA13330

NOTICE

TIP

• Valve clearance adjustment should be made

Before removing the spark plug, blow away

on a cold engine, at room temperature.

any dirt accumulated in the spark plug well

• When the valve clearance is to be measured or

with compressed air to prevent it from falling

adjusted, the piston must be at top dead center

into the cylinder.

(TDC) on the compression stroke.

3.

Check:

1.

Remove:

• Spark plug type

• Seat

Incorrect Change.

Refer to “GENERAL CHASSIS” on page 4-1.

Manufacturer/model

• Fuel tank

NGK/BPR6ES

Refer to “FUEL TANK” on page 6-1.

• Spark plug cap

4.

Check:

• Spark plug

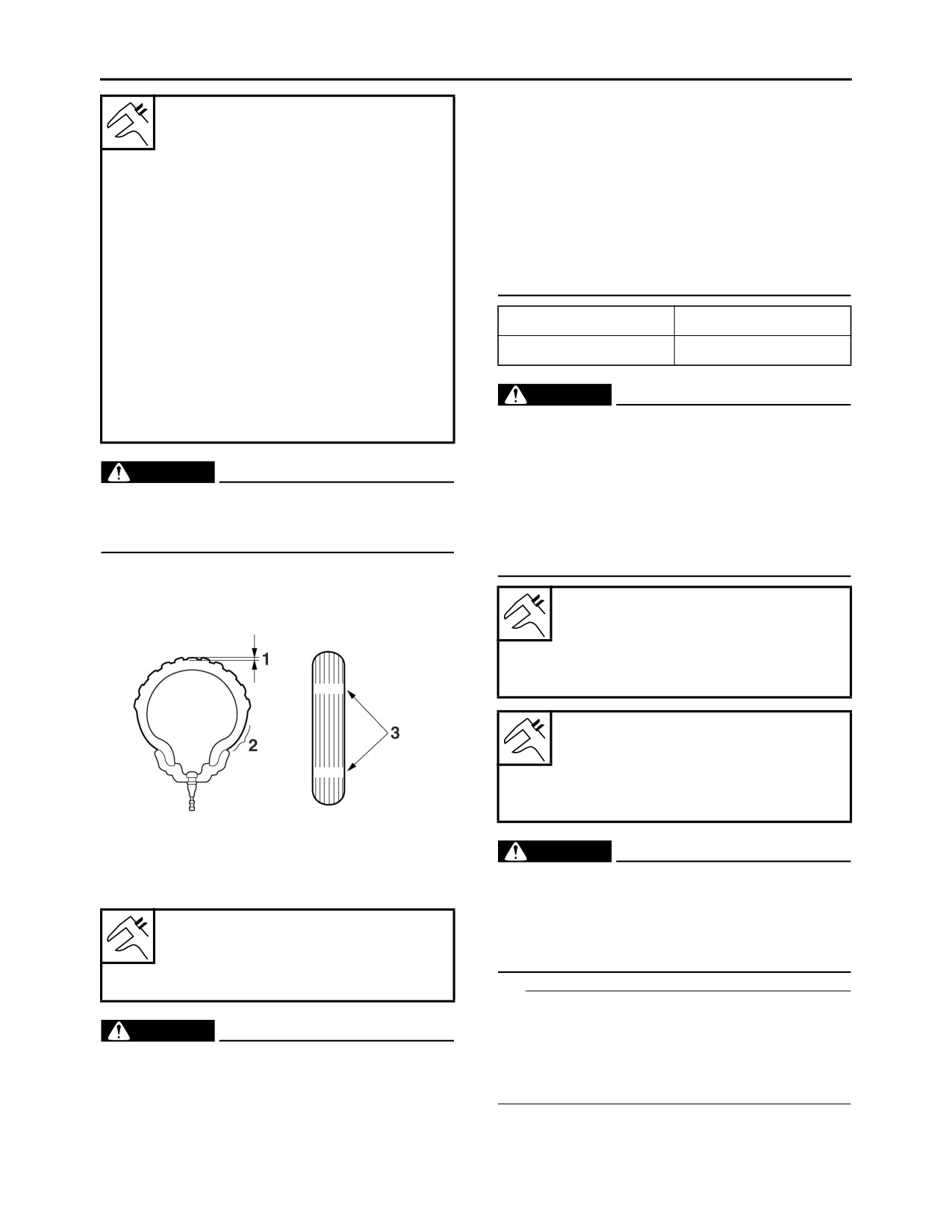

• Electrode “1”

• Exhaust tappet cover “1”

Damage/wear Replace the spark plug.

• Intake tappet cover “2”

• Insulator “2”

Refer to “CYLINDER HEAD” on page 5-7.

Abnormal color Replace the spark plug.

Normal color is medium-to-light tan.

2

5.

Clean:

• Spark plug

1

(with a spark plug cleaner or wire brush)

6.

Measure:

• Spark plug gap “a”

Out of specification Regap.

Spark plug gap

0.7-0.8 mm (0.028-0.031 in)

2.

Remove:

• Crankcase cover (left)

Refer to “GENERATOR” on page 5-47.

3.

Measure:

• Valve clearance

Out of specification Adjust.

Valve clearance (cold)

Intake

0.07-0.12 mm (0.0028-0.0047 in)

Exhaust

0.12-0.17 mm (0.0047-0.0067 in)

7.

Install:

• Spark plug

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

Spark plug

a. Turn the crankshaft counterclockwise.

25 Nm (2.5 m·kgf, 18 ft·lbf)

b. When the piston is on the compression

stroke, align AC magneto “T” mark “a” with

TIP

crankcase alignment mark “b”. (TDC)

Before installing the spark plug, clean the spark

3-5

PERIODIC MAINTENANCE

b

2

a

a

b

1

c. A position where the AC magneto “T” mark

Direction “a”

matches the crankcase alignment mark is the

Valve clearance is increased.

compression top dead center (TDC).

Direction “b”

d. Measure the valve clearance with a thickness

Valve clearance is decreased.

gauge “1”.

Out of specification Adjust.

Tappet adjusting tool (4 mm)

Thickness gauge

90890-04133

90890-03180

Six piece tappet set

Feeler gauge set

YM-A5970

YU-26900-9

• Hold the adjusting screw to prevent it from

moving and tighten the locknut to specifica-

tion.

Locknut

1

27 Nm (2.7 m·kgf, 20 ft·lbf)

d. Measure the valve clearance again.

e. If the valve clearance is still out of specifica-

tion, repeat all of the valve clearance adjust-

ment steps until the specified clearance is

obtained.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

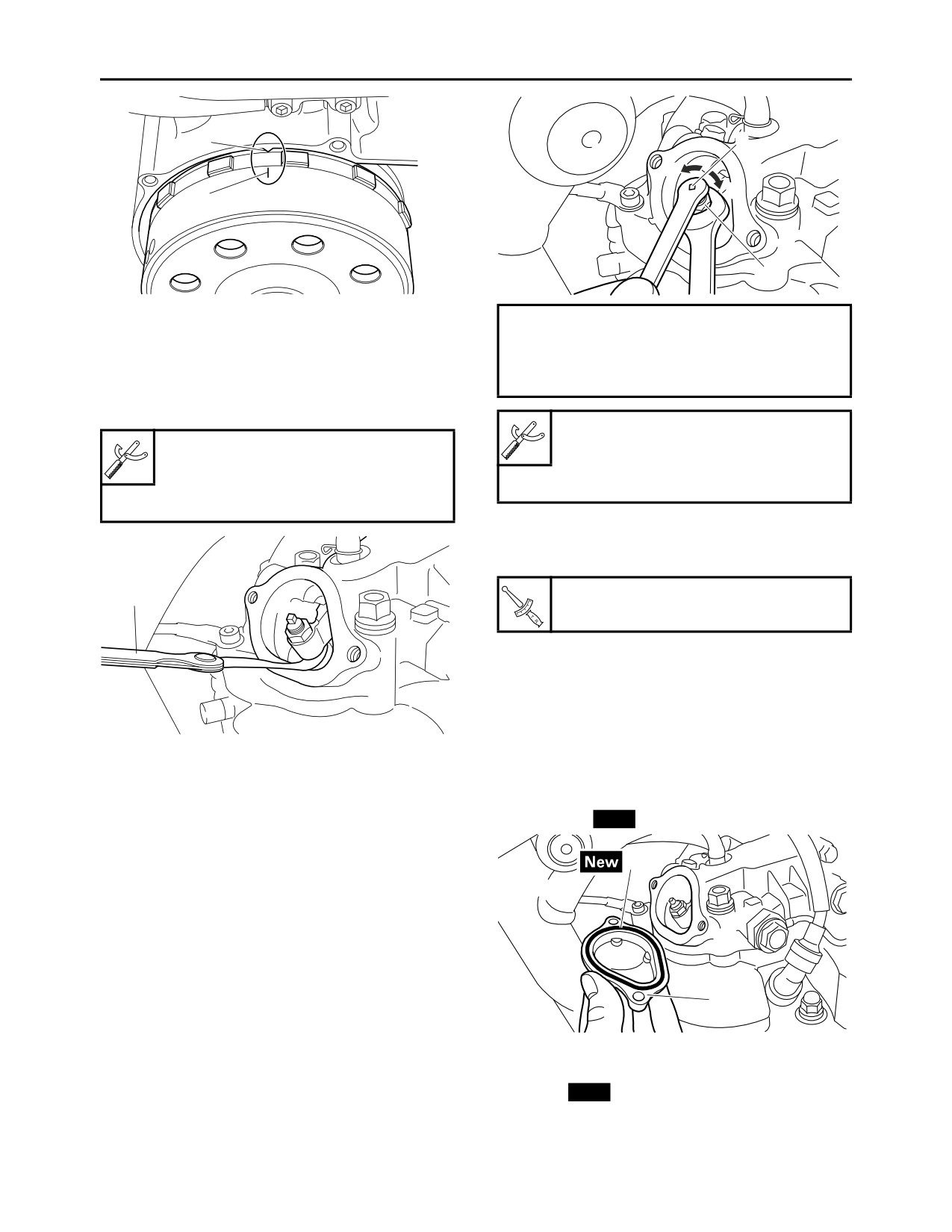

4. Adjust:

5. Install:

• Valve clearance

• Exhaust tappet cover “1”

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

• O-ring “2”

New

a. Loosen the locknut “1”.

b. Insert a thickness gauge between the end of

2

the adjusting screw and the valve stem end.

c. Turn the adjusting screw “2” in direction “a” or

“b” until the specified valve clearance is ob-

tained.

1

6. Install:

• Intake tappet cover

• O-ring

New

• Spark plug

• Spark plug cap

• Crankcase cover (left)

3-6

PERIODIC MAINTENANCE

Refer to “GENERATOR” on page 5-47.

Engine idling speed

• Fuel tank

1200-1400 r/min

Refer to “FUEL TANK” on page 6-1.

• Seat

EAS21020

Refer to “GENERAL CHASSIS” on page 4-1.

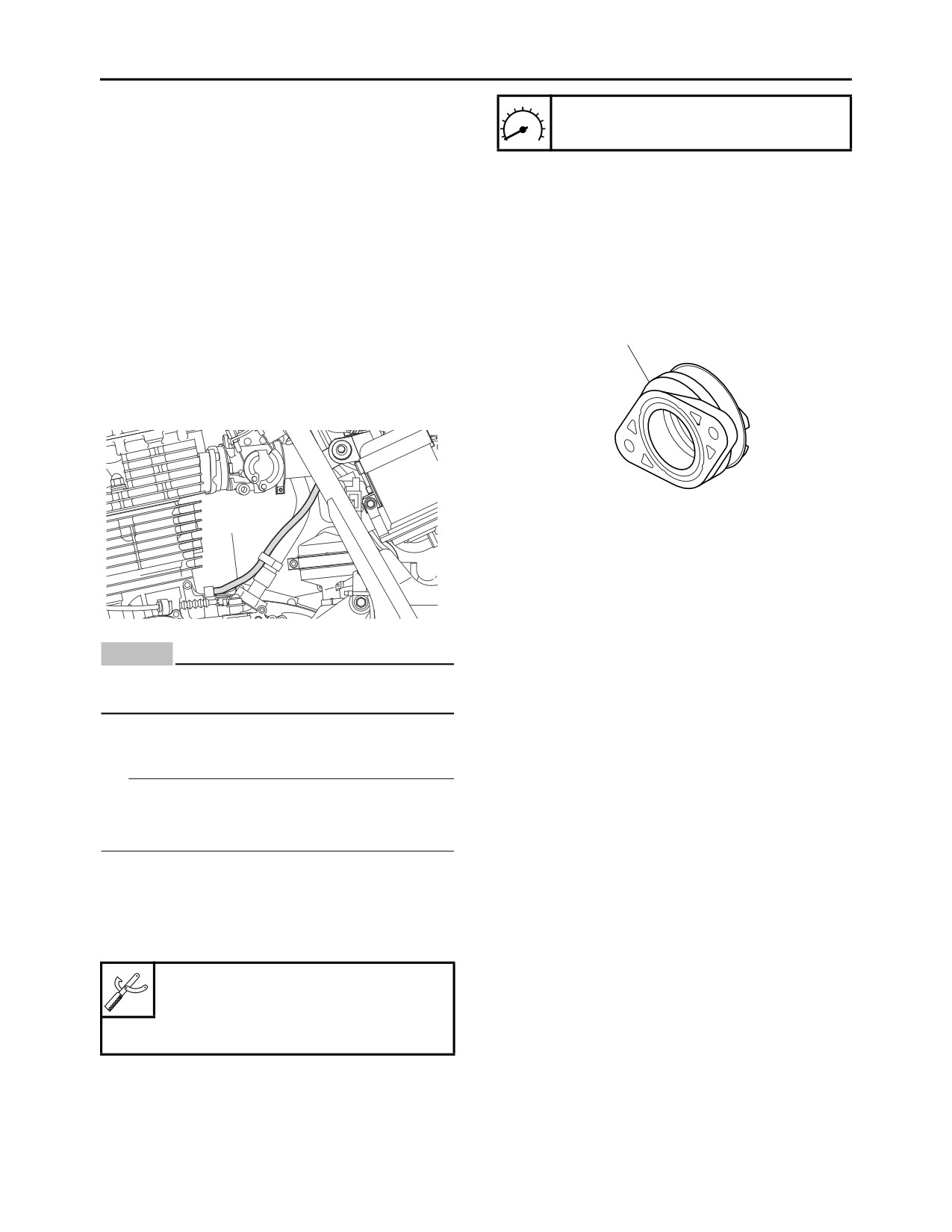

CHECKING THE THROTTLE BODY JOINT

7. Adjust:

1. Remove:

• Decompression lever free play

• Throttle body

Refer to “ADJUSTING THE DECOMPRES-

Refer to “THROTTLE BODY” on page 6-10.

SION LEVER FREE PLAY” on page 3-10.

2. Check:

EAS21070

• Throttle body joint “1”

CHECKING THE CRANKCASE BREATHER

Cracks/damage Replace.

HOSE

1

1. Check:

• Crankcase breather hose “1”

Cracks/damage Replace.

Loose connection Connect properly.

1

3. Install:

• Throttle body

Refer to “THROTTLE BODY” on page 6-10.

EAS21081

CHECKING THE EXHAUST SYSTEM

ECA13450

The following procedure applies to the exhaust

NOTICE

pipe and gasket.

Make sure the crankcase breather hose is

1. Remove:

routed correctly.

• Seat

Refer to “GENERAL CHASSIS” on page 4-1.

EAS2RD1006

• Fuel tank

CHECKING THE ENGINE IDLING SPEED

Refer to “FUEL TANK” on page 6-1.

TIP

2. Check:

Prior to checking the engine idling speed, the air

• Exhaust pipe “1”

filter element should be clean, and the engine

• Muffler “2”

should have adequate compression.

Cracks/damage Replace.

1. Start the engine and let it warm up for several

• Gasket “3”

minutes.

Exhaust gas leaks Replace the gasket.

2. Install:

• Digital tachometer

(To the spark plug lead)

Digital tachometer

90890-06760

Digital tachometer

YU-39951-B

3. Measure:

• Engine idling speed

Out of specification Replace the throttle

body.

3-7

PERIODIC MAINTENANCE

4. Install:

• Fuel tank

Refer to “FUEL TANK” on page 6-1.

• Seat

Refer to “GENERAL CHASSIS” on page 4-1.

2

EAS21090

CHECKING THE CANISTER (for California

only)

1. Check:

3

• Canister

• Canister purge hose

• Fuel tank breather hose

3

Cracks/damage Replace.

EAS2RD1009

CHECKING THE AIR INDUCTION SYSTEM

1

1. Check:

• Air induction system

Refer to “CHECKING THE AIR INDUCTION

SYSTEM” on page 6-18.

EAS2RD1008

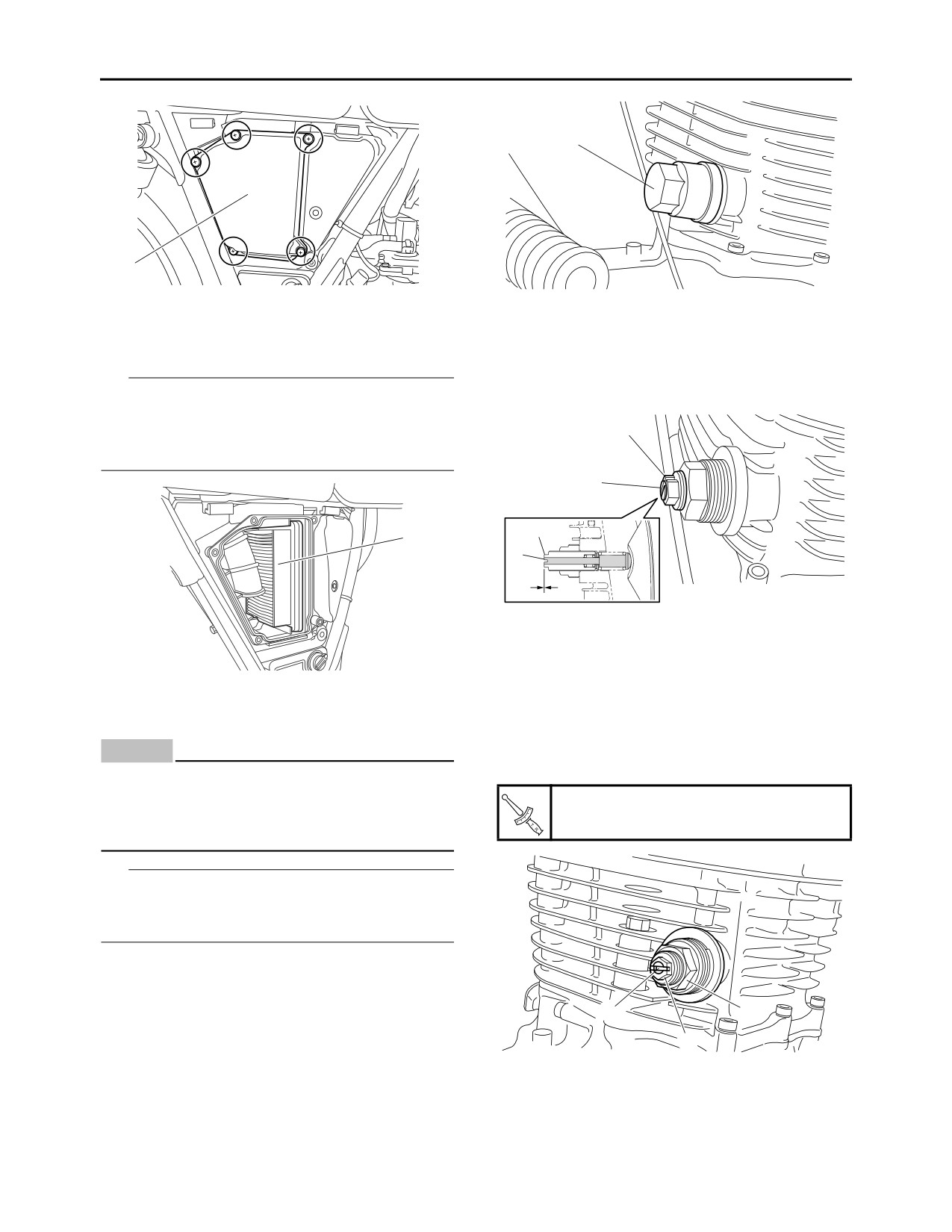

3. Check:

CHECKING THE OIL SEPARATOR

• Tightening torque

1. Check:

Exhaust pipe nut “1”

• Oil separator “1”

18 Nm (1.8 m·kgf, 13 ft·lbf)

Cracks/damage Replace.

Exhaust pipe and frame bolt “2”

Loose connections Tighten the clamp

23 Nm (2.3 m·kgf, 17 ft·lbf)

screw “2”.

Muffler joint bolt “3”

20 Nm (2.0 m·kgf, 14 ft·lbf)

Muffler bracket and frame bolt “4”

1

60 Nm (6.0 m·kgf, 43 ft·lbf)

Muffler and frame bracket bolt “5”

20 Nm (2.0 m·kgf, 14 ft·lbf)

2

5

EAS20961

REPLACING THE AIR FILTER ELEMENT

4

1. Remove:

• Side cover (right)

Refer to “GENERAL CHASSIS” on page 4-1.

3

2. Remove:

• Air filter case cover “1”

2

1

3-8

PERIODIC MAINTENANCE

1

1

3. Check:

2. Check:

• Air filter element “1”

• Rod “1”

Dirt/damage Replace.

Check if the rod end “1” is flush with the ad-

TIP

juster end “2”.

• Replace the air filter element every 19000 km

Not flush Adjust.

(12000 mi) of operation.

2

• The air filter needs more frequent service if you

are riding in unusually wet or dusty areas.

1

2

1

1

3. Adjust:

• Timing chain tension

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the timing chain tensioner locknut “1”.

4. Install:

b. Turn the adjuster “2” in or out until the rod end

• Air filter case cover

ECA2RD1018

“3” is flush with the adjuster end “2”.

NOTICE

c. Tighten the timing chain tensioner locknut

“1”.

Never operate the engine without the air filter

element installed. Failure to install the air fil-

Timing chain tensioner locknut

ter element may cause rapid wear of engine

38 Nm (3.8 m·kgf, 27 ft·lbf)

parts and may damage the engine.

TIP

When installing the air filter element into the air

filter case cover, make sure that the sealing sur-

faces are aligned to prevent any air leaks.

5. Install:

• Side cover (right)

Refer to “GENERAL CHASSIS” on page 4-1.

3

1

EAS2RD1011

CHECKING THE TIMING CHAIN TENSIONER

2

1. Remove:

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

• Timing chain tensioner cap “1”

4. Install:

• Timing chain tensioner cap

3-9

PERIODIC MAINTENANCE

EAS2RD1007

Timing chain tensioner cap

ADJUSTING THE DECOMPRESSION LEVER

18 Nm (1.8 m·kgf, 13 ft·lbf)

FREE PLAY

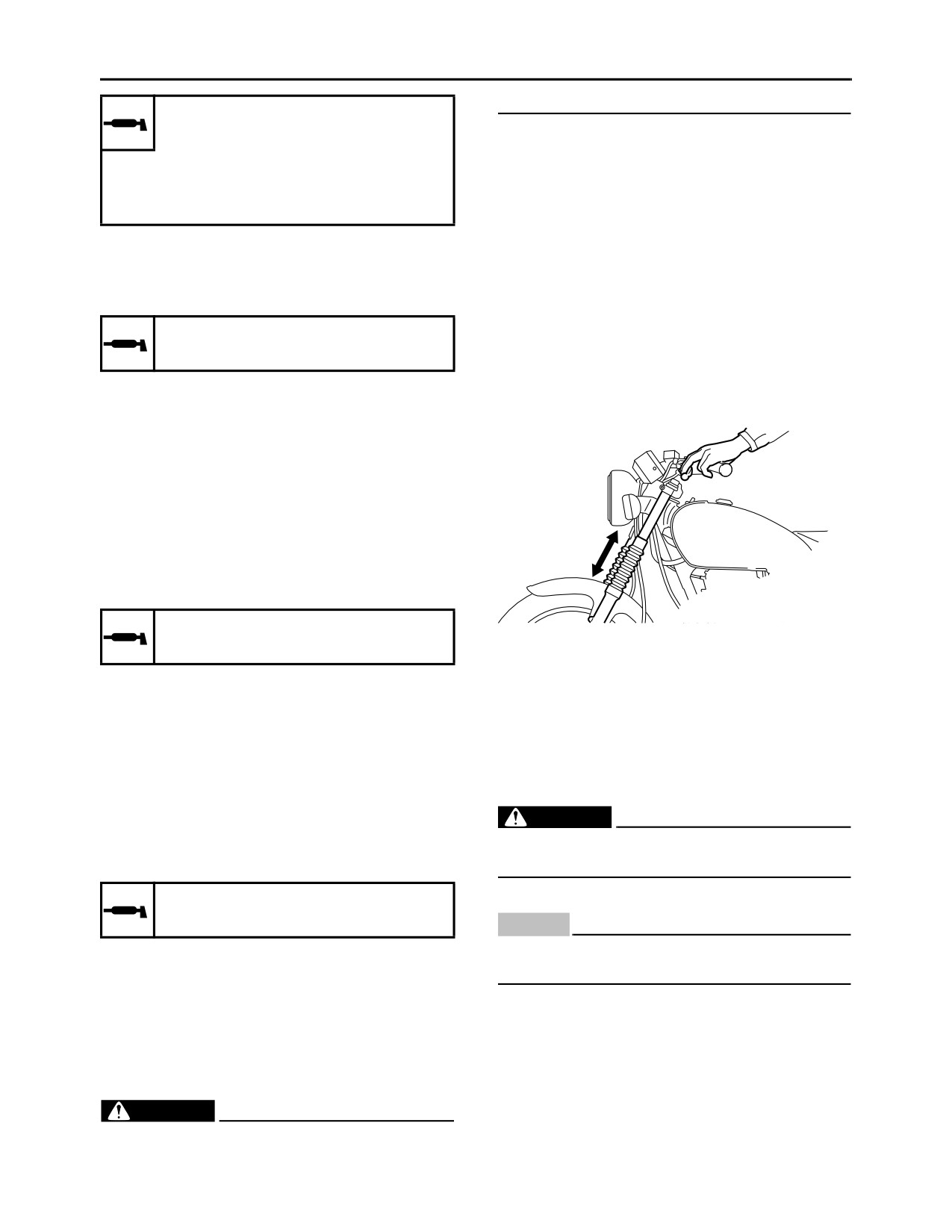

1. Fully turn the handle to the left.

EAS20870

2. Remove:

ADJUSTING THE CLUTCH LEVER FREE

• Spark plug cap

PLAY

• Spark plug

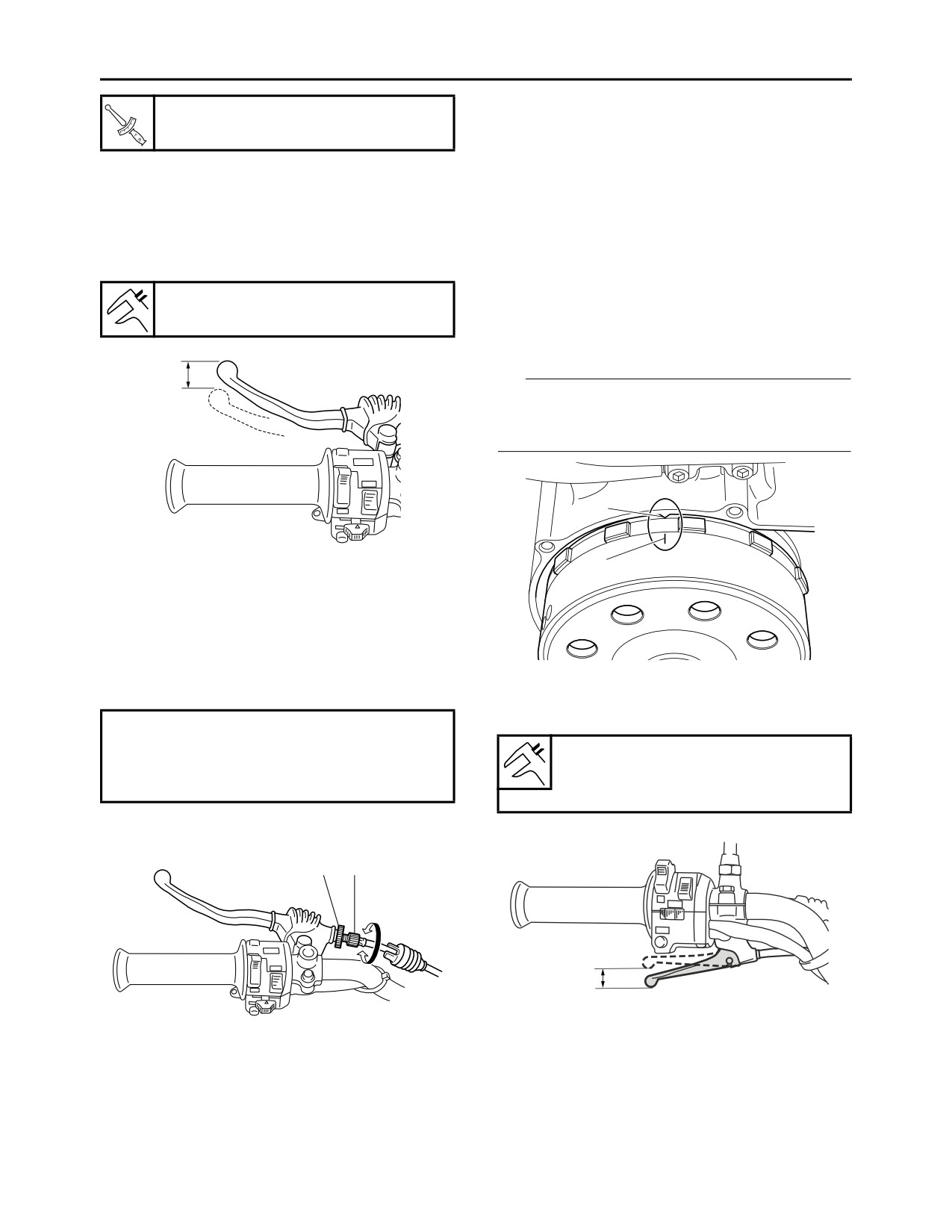

1. Check:

3. Remove:

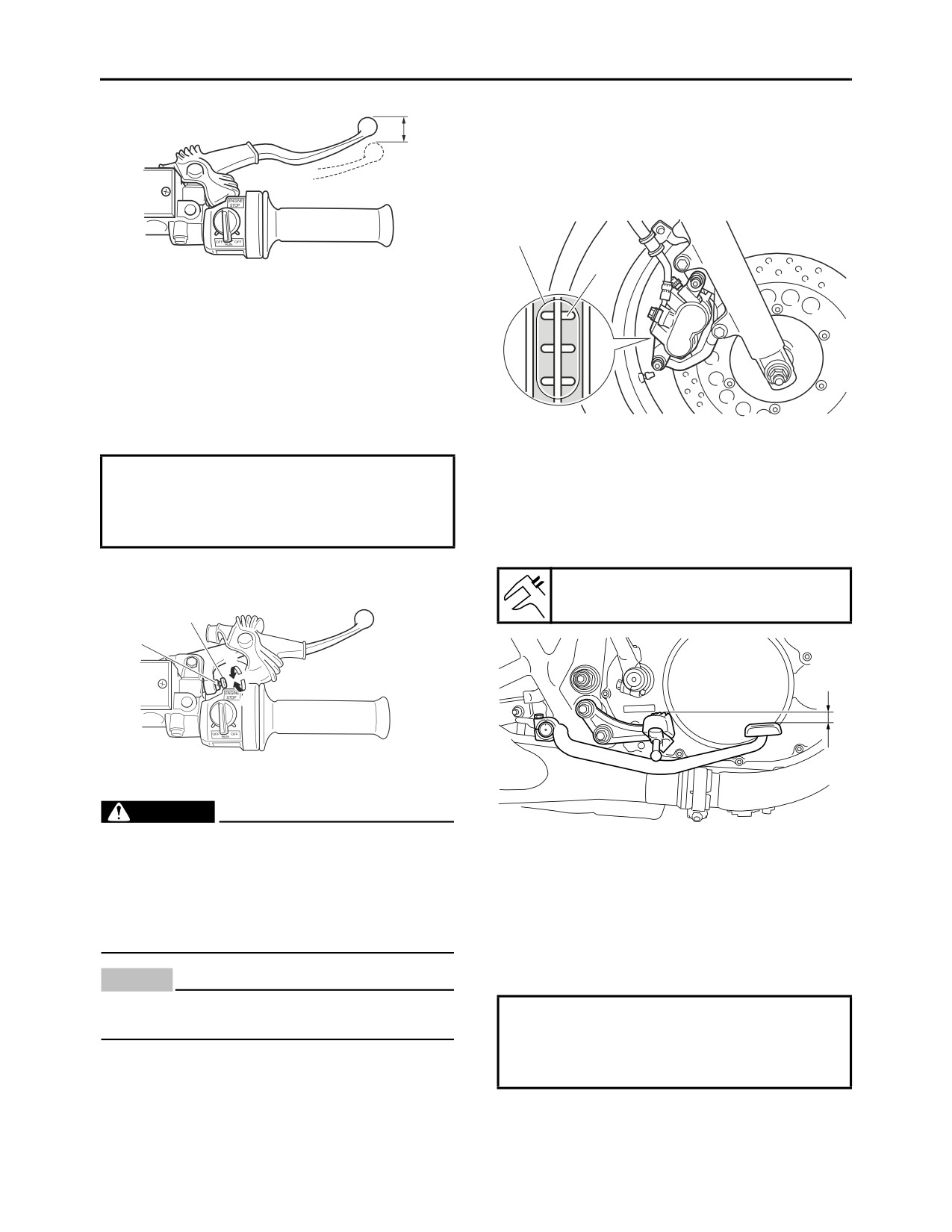

• Clutch lever free play “a”

• Crankcase cover (left)

Out of specification Adjust.

Refer to “GENERATOR” on page 5-47.

4. Turn the AC magneto counterclockwise and

Clutch lever free play

5.0-10.0 mm (0.20-0.39 in)

align the “T” mark “a” of the AC magneto with

the matching mark “b” of the crankcase at

compression top dead center.

a

TIP

A position where the AC magneto “T” mark

matches the crankcase matching mark is the

compression top dead center (TDC).

b

a

2. Adjust:

• Clutch lever free play

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the locknut “1”.

b. Turn the adjusting bolt “2” in direction “a” or

“b” until the specified clutch lever free play is

5. Check:

obtained.

• Decompression lever free play “a”

Out of specification Adjust.

Direction “a”

Clutch lever free play is increased.

Decompression lever free play

Direction “b”

(decompression lever end)

Clutch lever free play is decreased.

5.0-10.0 mm (0.20-0.39 in)

c. Tighten the locknut “1”.

1

2

a

b

a

6. Adjust:

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

• Decompression lever free play

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the locknut “1”.

b. Turn the adjusting nut “2” in direction “a” or “b”

until specified decompression lever free play

3-10

PERIODIC MAINTENANCE

is obtained.

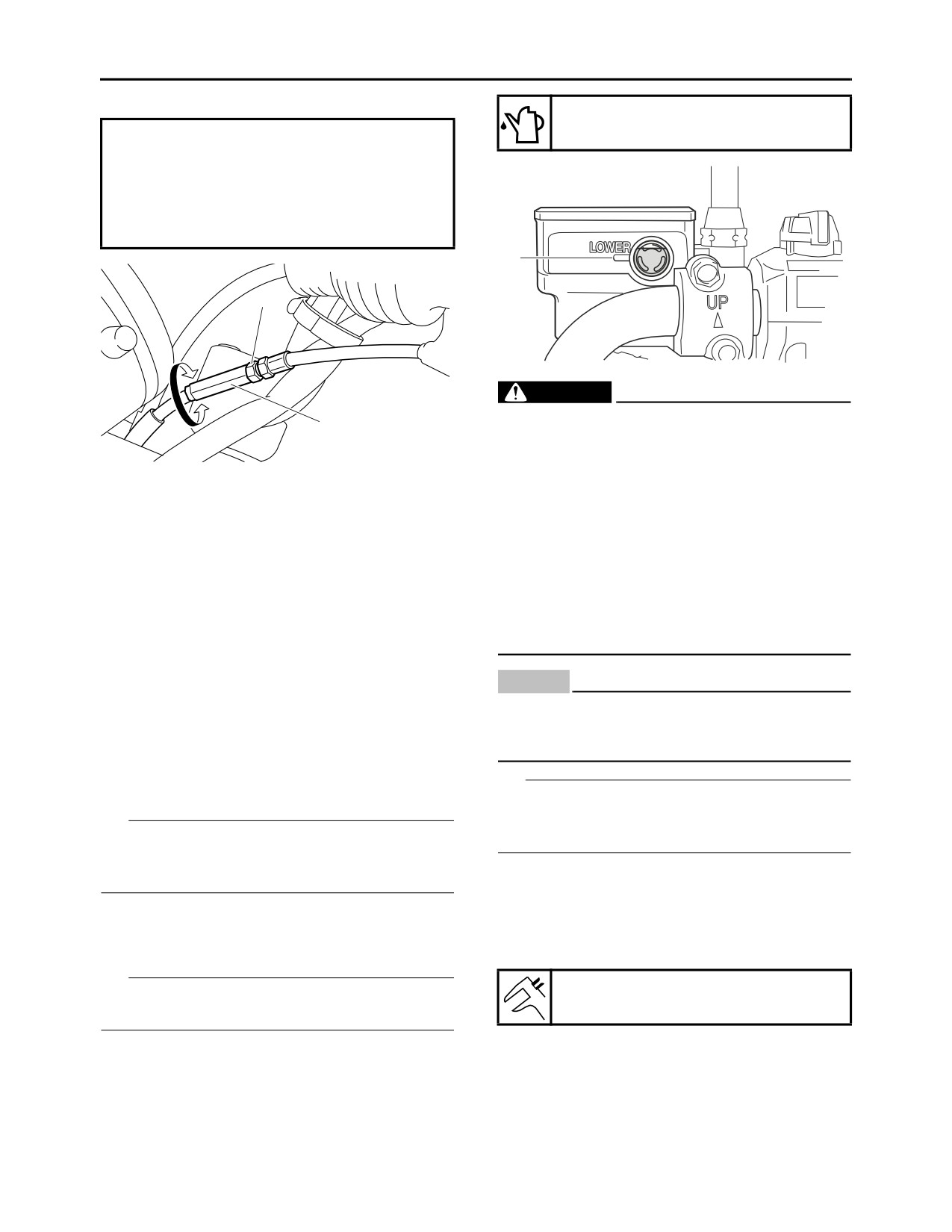

Specified brake fluid

DOT 4

Direction “a”

Decompression lever free play is in-

creased.

Direction “b”

Decompression lever free play is de-

creased.

a

1

b

EWA13090

WARNING

a

• Use only the designated brake fluid. Other

2

brake fluids may cause the rubber seals to

deteriorate, causing leakage and poor

c. Tighten the locknut.

brake performance.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

• Refill with the same type of brake fluid that

is already in the system. Mixing brake fluids

7. Install:

may result in a harmful chemical reaction,

• Crankcase cover (left)

leading to poor brake performance.

Refer to “GENERATOR” on page 5-47.

• When refilling, be careful that water does

8. Install:

not enter the brake fluid reservoir. Water

• Spark plug

will significantly lower the boiling point of

• Spark plug cap

the brake fluid and could cause vapor lock.

EAS2RD1020

ECA13540

CHECKING THE BRAKE OPERATION

NOTICE

1. Check:

Brake fluid may damage painted surfaces

• Brake operation

and plastic parts. Therefore, always clean up

Brake not working properly Check the

any spilt brake fluid immediately.

brake system.

Refer to “FRONT BRAKE” on page 4-17 and

TIP

“REAR BRAKE” on page 4-30.

In order to ensure a correct reading of the brake

TIP

fluid level, make sure the top of the brake fluid

Drive on the dry road, operate the front and rear

reservoir is horizontal.

brakes separately and check to see if the brakes

are operating properly.

EAS21170

ADJUSTING THE FRONT DISC BRAKE

EAS21240

1. Check:

CHECKING THE BRAKE FLUID LEVEL

• Brake lever free play “a”

1. Stand the vehicle on a level surface.

Out of specification Adjust.

TIP

Front brake lever free play

• Place the vehicle on a suitable stand.

5.0-8.0 mm (0.20-0.31 in)

• Make sure the vehicle is upright.

2. Check:

• Brake fluid level

Below the minimum level mark “a” Add the

specified brake fluid to the proper level.

3-11

PERIODIC MAINTENANCE

1. Operate the brake.

2. Check:

a

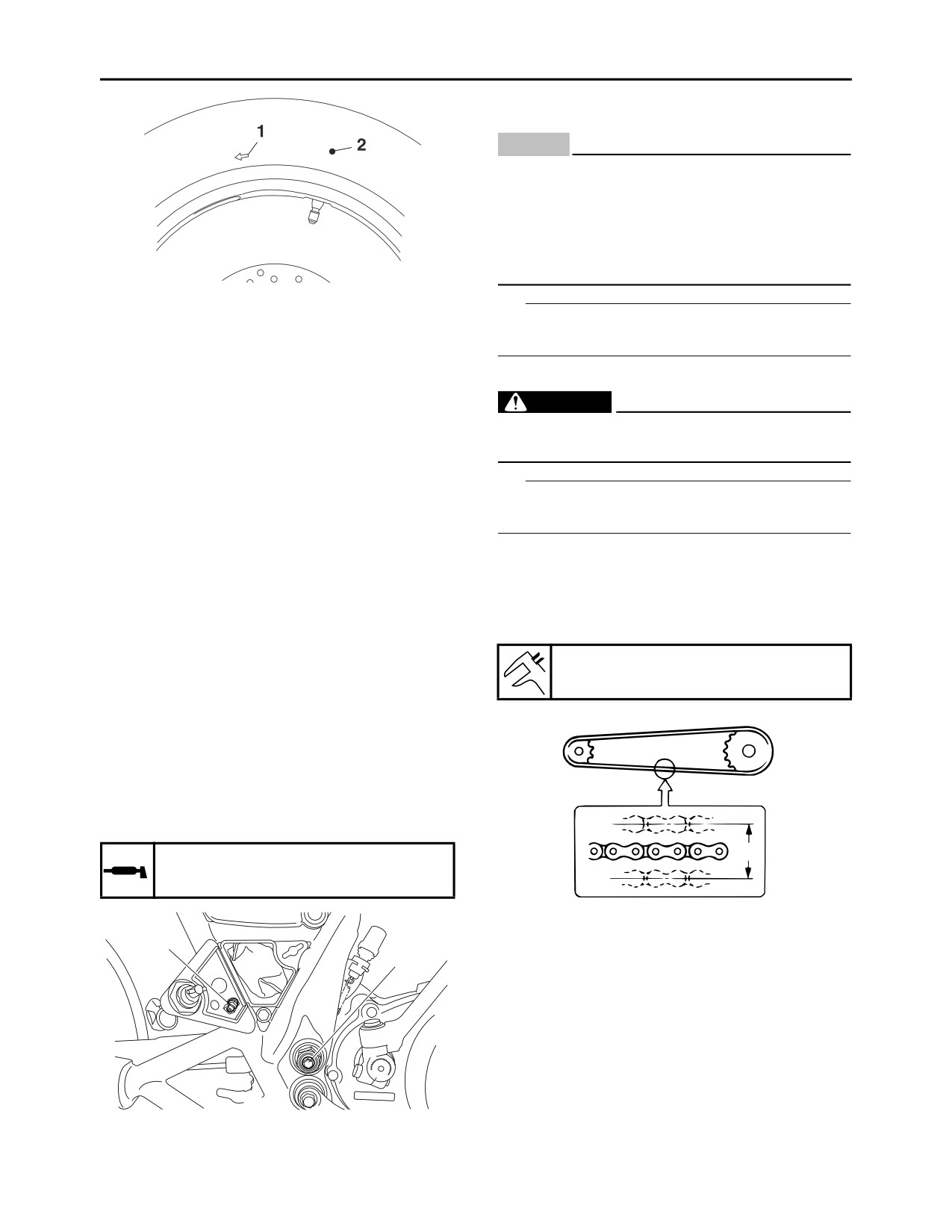

• Front brake pad “1”

Wear indicator grooves “2” almost disap-

peared Replace the brake pads as a set.

Refer to “FRONT BRAKE” on page 4-17.

1

2

2. Adjust:

• Brake lever free play

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the locknut “1”.

b. Turn the adjusting screw “2” in direction “a” or

“b” until the specified brake lever free play is

EAS21220

obtained.

ADJUSTING THE REAR DRUM BRAKE

Direction “a”

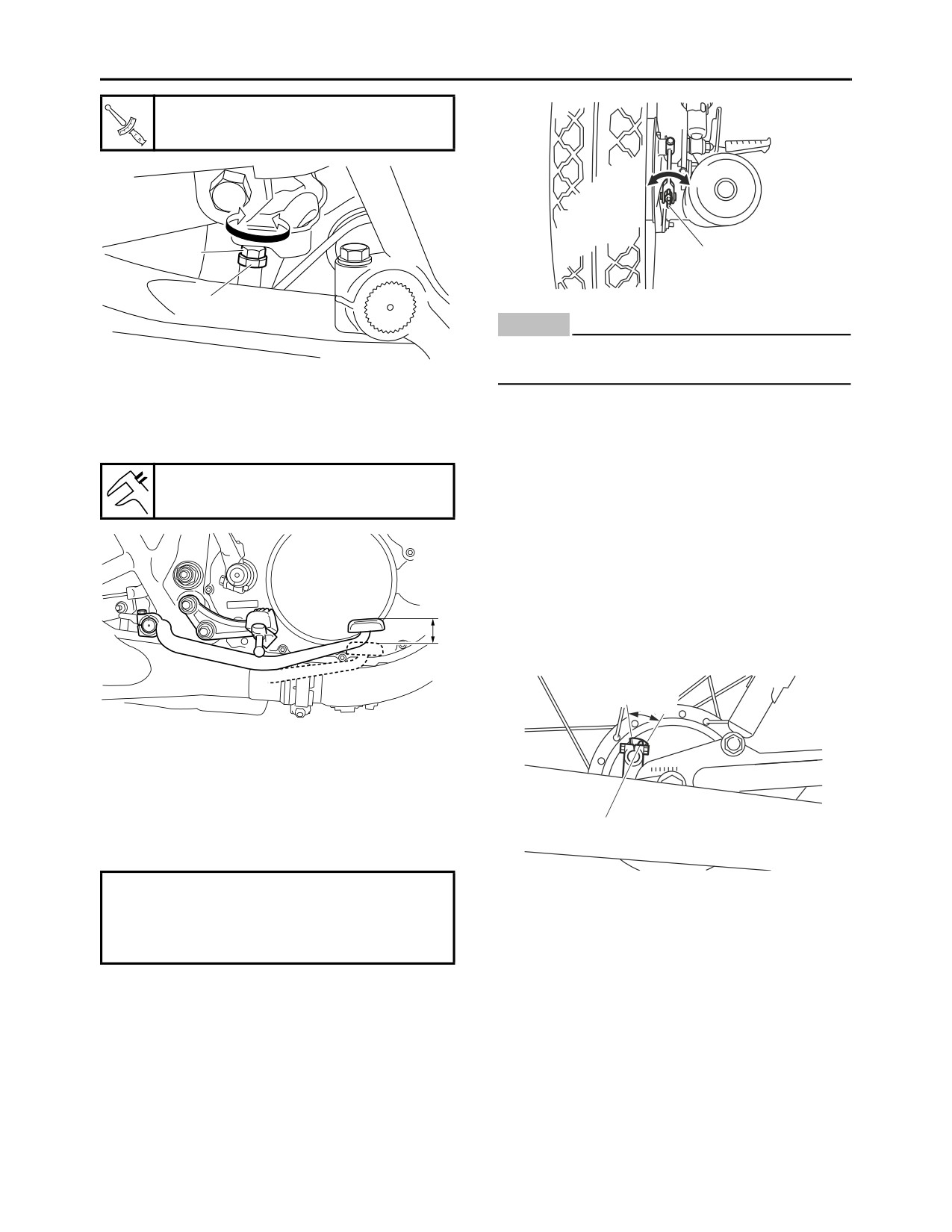

1. Check:

Brake lever free play is increased.

• Brake pedal position

Direction “b”

(distance “a” from the top of the rider footrest

Brake lever free play is decreased.

to the top of the brake pedal)

Out of specification Adjust.

c. Tighten the locknut “1”.

Brake pedal position

20.0 mm (0.79 in)

2

1

a

b

a

EWA13050

WARNING

A soft or spongy feeling in the brake lever

2. Adjust:

can indicate the presence of air in the brake

• Brake pedal position

system. Before the vehicle is operated, the

air must be removed by bleeding the brake

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

system. Air in the brake system will consid-

a. Loosen the locknut “1”.

erably reduce braking performance.

b. Turn the adjusting bolt “2” in direction “a” or

“b” until the specified brake pedal position is

ECA13490

obtained.

NOTICE

After adjusting the brake lever position,

Direction “a”

make sure there is no brake drag.

Brake pedal is lowered.

Direction “b”

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Brake pedal is raised.

EAS21250

CHECKING THE FRONT BRAKE PADS

c. Tighten the locknut “1” to specification.

The following procedure applies to all of the

brake pads.

3-12

PERIODIC MAINTENANCE

Locknut

7 Nm (0.7 m·kgf, 5.1 ft·lbf)

a

b

b

a

2

1

1

ECA13520

NOTICE

After adjusting the brake pedal position and

free play, make sure there is no brake drag.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Check:

• Brake pedal free play “a”

5. Adjust:

Out of specification Adjust.

• Rear brake light switch

Refer to “ADJUSTING THE REAR BRAKE

Brake pedal free play

LIGHT SWITCH” on page 3-23.

20.0-30.0 mm (0.79-1.18 in)

EAS21310

CHECKING THE REAR BRAKE SHOES

1. Operate the brake.

2. Check:

• Brake shoe wear indicator “1”

Reaches the wear limit line “2” Replace the

a

brake shoes as a set.

Refer to “REAR BRAKE” on page 4-30.

2

4. Adjust:

• Brake pedal free play

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the adjusting nut “1” in direction “a” or “b”

1

until the specified brake pedal free play is ob-

tained.

Direction “a”

EAS21270

Brake pedal free play is increased.

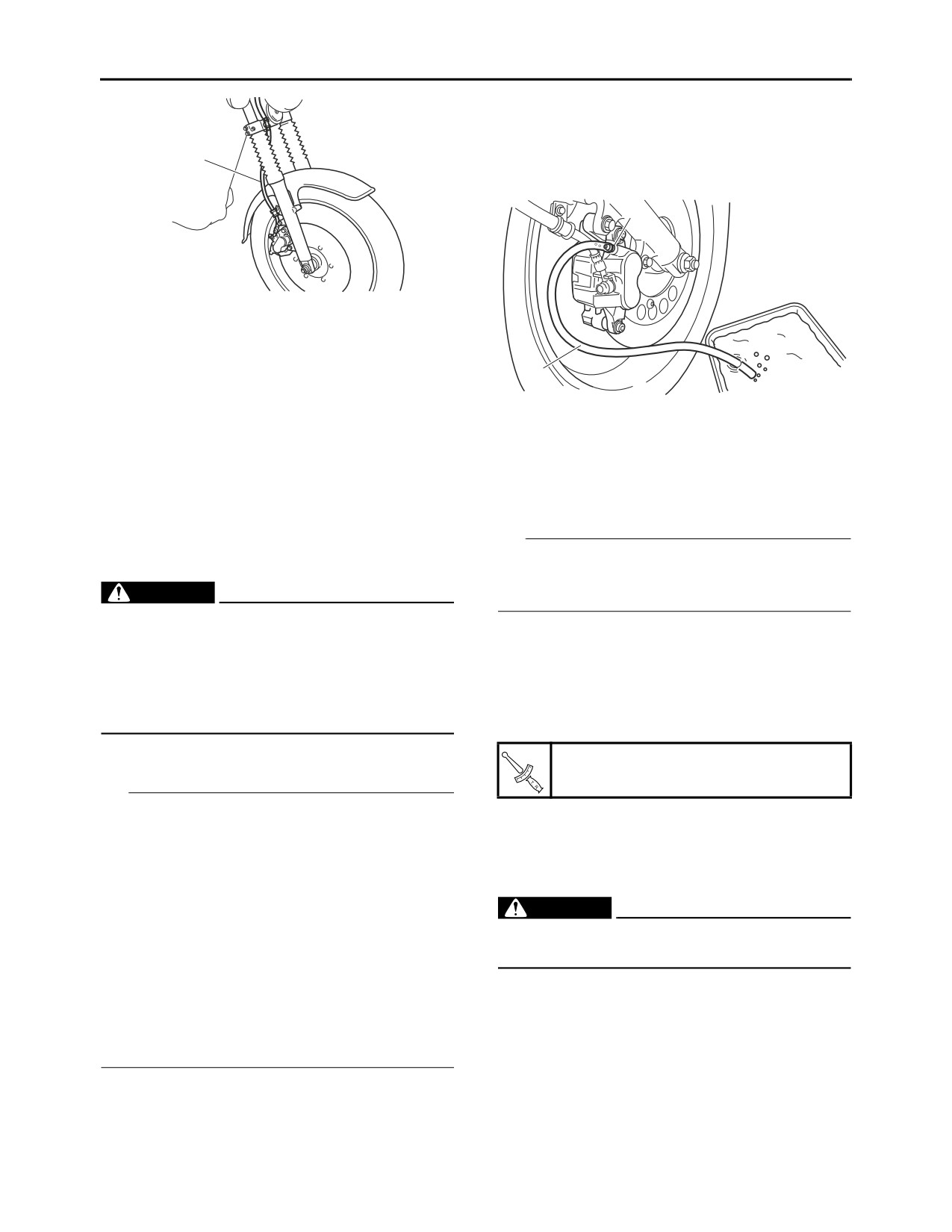

CHECKING THE FRONT BRAKE HOSE

Direction “b”

1. Check:

Brake pedal free play is decreased.

• Brake hose “1”

Cracks/damage/wear Replace.

3-13

PERIODIC MAINTENANCE

with the specified brake fluid.

b. Install the brake master cylinder reservoir di-

aphragm.

1

c. Connect a clear plastic hose “1” tightly to the

bleed screw “2”.

2

2. Check:

• Brake hose clamp

Loose Tighten the clamp bolt.

3. Hold the vehicle upright and apply the front

1

brake several times.

4. Check:

d. Place the other end of the hose into a con-

• Brake hose

tainer.

Brake fluid leakage Replace the damaged

e. Slowly apply the brake lever several times.

hose.

f. Fully pull the brake lever and hold it in posi-

Refer to “FRONT BRAKE” on page 4-17.

tion.

g. Loosen the bleed screw.

EAS21340

TIP

BLEEDING THE HYDRAULIC BRAKE

Loosening the bleed screw will release the pres-

SYSTEM

EWA13100

sure and cause the brake lever to contact the

WARNING

throttle grip.

Bleed the hydraulic brake system whenever:

h. Tighten the bleed screw and then release the

• the system is disassembled.

brake lever.

• a brake hose is loosened, disconnected or

i. Repeat steps (e) to (h) until all of the air bub-

replaced.

bles have disappeared from the brake fluid in

• the brake fluid level is very low.

the plastic hose.

• brake operation is faulty.

j. Tighten the bleed screw to specification.

1. Remove:

Bleed screw

• Reservoir cap

6 Nm (0.6 m·kgf, 4.3 ft·lbf)

TIP

• Be careful not to spill any brake fluid or allow

k. Fill the brake fluid reservoir to the proper level

the brake master cylinder reservoir or brake

with the specified brake fluid.

fluid reservoir to overflow.

Refer to “CHECKING THE BRAKE FLUID

• When bleeding the hydraulic brake system,

LEVEL” on page 3-11.

make sure there is always enough brake fluid

EWA13110

before applying the brake. Ignoring this pre-

WARNING

caution could allow air to enter the hydraulic

After bleeding the hydraulic brake system,

brake system, considerably lengthening the

check the brake operation.

bleeding procedure.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

• If bleeding is difficult, it may be necessary to let

the brake fluid settle for a few hours. Repeat

EAS21670

the bleeding procedure when the tiny bubbles

CHECKING THE WHEELS

in the hose have disappeared.

The following procedure applies to both of the

wheels.

2. Bleed:

1. Check:

• Hydraulic brake system

• Wheel

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

Damage/out-of-round Replace.

a. Fill the brake fluid reservoir to the proper level

3-14

PERIODIC MAINTENANCE

EWA13260

WARNING

Never attempt to make any repairs to the

1

wheel.

TIP

After a tire or wheel has been changed or re-

placed, always balance the wheel.

EAS21681

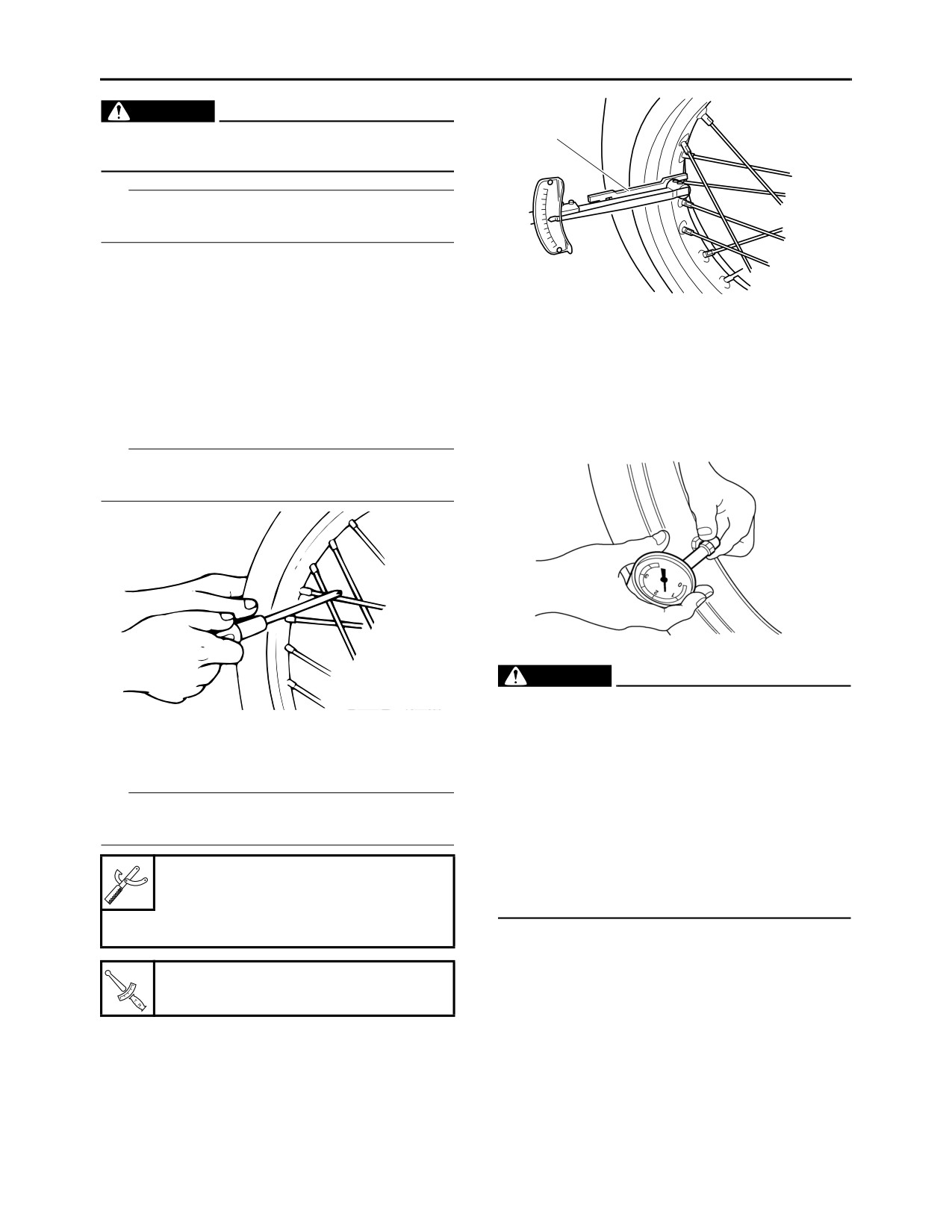

CHECKING AND TIGHTENING THE SPOKES

The following procedure applies to all of the

EAS21650

spokes.

CHECKING THE TIRES

1. Check:

The following procedure applies to both of the

• Spoke

tires.

Bends/damage Replace.

1. Check:

Loose Tighten.

• Tire pressure

Tap the spokes with a screwdriver.

Out of specification Regulate.

TIP

A tight spoke will emit a clear, ringing tone; a

loose spoke will sound flat.

EWA1

3180

WARNING

•T

he tire pressure should only be checked

and regulated when the tire temperature

2. Tighten:

equals the ambient air temperature.

• Spoke

• The tire pressure and the suspension must

(with a spoke nipple wrench “1”)

be adjusted according to the total weight

TIP

(including cargo, rider, passenger and ac-

Be sure to tighten the spokes before and after

cessories) and the anticipated riding

break-in.

speed.

• Operation of an overloaded vehicle could

Spoke nipple wrench (8-9)

cause tire damage, an accident or an injury.

90890-01522

NEVER OVERLOAD THE VEHICLE.

Spoke nipple wrench (8-9)

YM-01522

Spoke

3.0 Nm (0.30 m·kgf, 2.2 ft·lbf)

3-15

PERIODIC MAINTENANCE

• Always replace a new tube tire and a new

Tire air pressure (measured on

tube as a set.

cold tires)

• To avoid pinching the tube, make sure the

Loading condition

wheel rim band and tube are centered in the

0-90 kg (0-198 lb)

wheel groove.

Front

• Patching a punctured tube is not recom-

175 kPa (1.75 kgf/cm², 25 psi)

Rear

mended. If it is absolutely necessary to do

200 kPa (2.00 kgf/cm², 29 psi)

so, use great care and replace the tube as

Loading condition

soon as possible with a good quality re-

90-150 kg (198-331 lb)

placement.

Front

200 kPa (2.00 kgf/cm², 29 psi)

Tube wheel

Tube tire only

Rear

Tubeless wheel

Tube or tubeless tire

225 kPa (2.25 kgf/cm², 33 psi)

Maximum load

EWA14090

150 kg (331 lb)

WARNING

* Total weight of rider, passenger, cargo

After extensive tests, the tires listed below

and accessories

have been approved by Yamaha Motor Co.,

EWA13190

Ltd. for this model. The front and rear tires

WARNING

should always be by the same manufacturer

It is dangerous to ride with a worn-out tire.

and of the same design. No guarantee con-

When the tire tread reaches the wear limit, re-

cerning handling characteristics can be giv-

place the tire immediately.

en if a tire combination other than one

approved by Yamaha is used on this vehicle.

2. Check:

• Tire surfaces

Front tire

Damage/wear Replace the tire.

Size

90/100-18M/C 54S

Manufacturer/model

BRIDGESTONE/BT-45

Rear tire

Size

110/90-18M/C 61S

Manufacturer/model

BRIDGESTONE/BT-45

EWA13210

1. Tire tread depth

WARNING

2. Side wall

New tires have a relatively low grip on the

3. Wear indicator

road surface until they have been slightly

worn. Therefore, approximately

100 km

Wear limit (front)

should be traveled at normal speed before

1.0 mm (0.04 in)

any high-speed riding is done.

Wear limit (rear)

1.0 mm (0.04 in)

TIP

For tires with a direction of rotation mark “1”:

EWA14080

• Install the tire with the mark pointing in the di-

WARNING

rection of wheel rotation.

• Do not use a tubeless tire on a wheel de-

• Align the mark “2” with the valve installation

signed only for tube tires to avoid tire fail-

point.

ure and personal injury from sudden

deflation.

• When using a tube tire, be sure to install the

correct tube.

3-16

PERIODIC MAINTENANCE

EAS21390

ADJUSTING THE DRIVE CHAIN SLACK

ECA13550

NOTICE

A drive chain that is too tight will overload

the engine and other vital parts, and one that

is too loose can skip and damage the swing-

arm or cause an accident. Therefore, keep

the drive chain slack within the specified lim-

its.

TIP

EAS2RD1021

The drive chain slack must be checked at the

CHECKING THE WHEEL BEARINGS

tightest point on the chain.

The following procedure applies to all of the

wheel bearings.

1. Stand the vehicle on a level surface.

EWA13120

1. Check:

WARNING

• Wheel bearing

Refer to “CHECKING THE FRONT WHEEL”

Securely support the vehicle so that there is

on page 4-7 and “CHECKING THE REAR

no danger of it falling over.

WHEEL” on page 4-14.

TIP

EAS2RD1022

Place the vehicle on a suitable stand so that the

CHECKING THE SWINGARM OPERATION

rear wheel is elevated.

1. Check:

2. Move the rear wheel several times and find

• Swingarm operation

the tightest position of drive chain.

Swingarm not working properly Check the

3. Check:

swingarm.

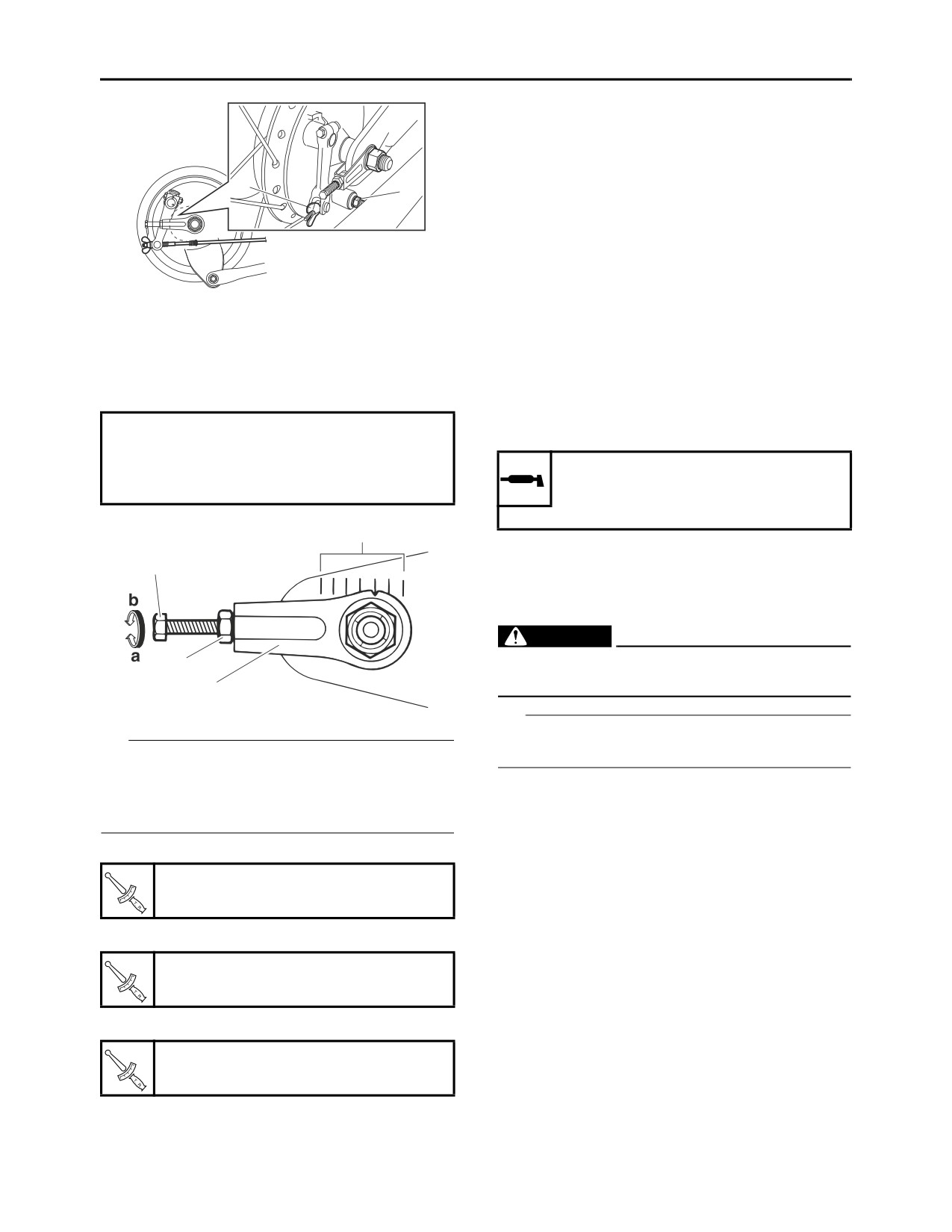

• Drive chain slack “a”

Refer to “REAR SHOCK ABSORBER AS-

Out of specification Adjust.

SEMBLY AND SWINGARM” on page 4-48.

2. Check:

Drive chain slack

• Swingarm excessive play

30.0-40.0 mm (1.18-1.57 in)

Refer to “REAR SHOCK ABSORBER AS-

SEMBLY AND SWINGARM” on page 4-48.

EAS2RD1029

LUBRICATING THE SWINGARM

Remove the bolts “1” at both ends of the pivot

shaft and install the grease nipple “2” to the pivot

shaft before lubrication.

a

Recommended lubricant

Lithium-soap-based grease

4. Adjust:

2

• Drive chain slack

1

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen wheel axle nut “1”.

b. Loosen the brake pedal free play adjusting

nut “2” and tension bar nut “3”.

3-17

PERIODIC MAINTENANCE

EAS21440

LUBRICATING THE DRIVE CHAIN

1

The drive chain consists of many interacting

parts. If the drive chain is not maintained proper-

ly, it will wear out quickly. Therefore, the drive

2

3

chain should be serviced, especially when the

vehicle is used in dusty areas.

This vehicle has a drive chain with small rubber

O-rings between each side plate. Steam clean-

ing, high-pressure washing, certain solvents,

and the use of a coarse brush can damage

c. Loosen the locknut “4” on each end of the

these O-rings. Therefore, use only kerosene to

swingarm.

clean the drive chain. Wipe the drive chain dry

d. Turn the adjusting bolt “5” on each end of the

and thoroughly lubricate it with engine oil or

swingarm in direction “a” or “b” until the spec-

chain lubricant that is suitable for O-ring chains.

ified drive chain slack is obtained.

Do not use any other lubricants on the drive

chain since they may contain solvents that could

Direction “a”

damage the O-rings.

Drive chain is tightened.

Direction “b”

Recommended lubricant

Drive chain is loosened.

Chain lubricant suitable for O-

ring chains

c

EAS21510

5

CHECKING AND ADJUSTING THE

STEERING HEAD

1. Stand the vehicle on a level surface.

EWA13120

WARNING

4

Securely support the vehicle so that there is

d

no danger of it falling over.

TIP

Place the vehicle on a suitable stand so that the

TIP

front wheel is elevated.

Using the alignment marks “c” on each end of

the swingarm, make sure that both drive chain

2. Check:

pullers “d” are in the same position for proper

• Steering head

wheel alignment.

Grasp the bottom of the front fork legs and

gently rock the front fork.

e. Tighten the wheel axle nut to specification.

Binding/looseness

Adjust the steering

Wheel axle nut

head.

129 Nm (12.9 m·kgf, 93 ft·lbf)

3. Remove:

• Upper bracket

f. Tighten the locknuts to specification.

Refer to “STEERING HEAD” on page 4-44.

4. Adjust:

Locknut

16 Nm (1.6 m·kgf, 12 ft·lbf)

• Steering head

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

g. Tighten the tension bar nut to specification.

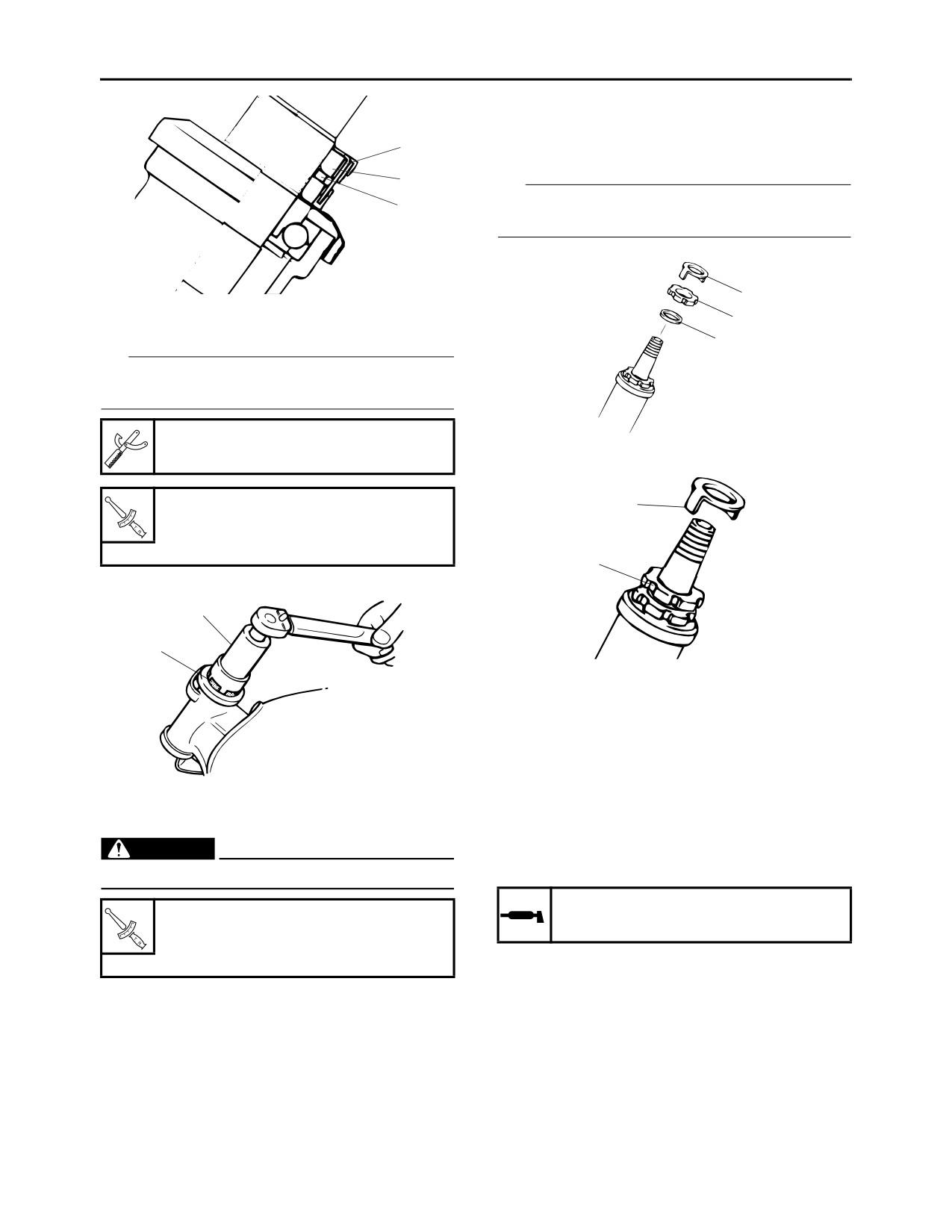

a. Remove the lock washer “1”, upper ring nut

“2”, and rubber washer “3”.

Tension bar nut

19 Nm (1.9 m·kgf, 14 ft·lbf)

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3-18

PERIODIC MAINTENANCE

g. Finger tighten the upper ring nut, then align

the slots of both ring nuts. If necessary, hold

the lower ring nut and tighten the upper ring

1

nut until their slots are aligned.

2

TIP

3

Make sure the lock washer “3” tab “a” sit correct-

ly in the ring nut slots “b”.

3

b. Tighten the lower ring nut “4” to specification

2

with a steering nut wrench “5”.

1

TIP

Set the torque wrench at a right angle to the

steering nut wrench.

Steering nut wrench

90890-01385

Lower ring nut (initial tightening

a

torque)

38 Nm (3.8 m·kgf, 27 ft·lbf)

b

5

4

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. Install:

• Upper bracket

Refer to “STEERING HEAD” on page 4-44.

354-017

EAS2RD1024

LUBRICATING THE STEERING HEAD

c. After fully loosening the lower ring nut, tighten

1. Lubricate:

it to specification with a steering nut wrench.

EWA13140

• Upper bearing

WARNING

• Lower bearing

Do not overtighten the lower ring nut.

• Bearing race

Recommended lubricant

Lower ring nut (final tightening

Lithium-soap-based grease

torque)

18 Nm (1.8 m·kgf, 13 ft·lbf)

EAS2RD1025

CHECKING THE CHASSIS FASTENERS

d. Check the steering head for looseness or

Make sure that all nuts, bolts, and screws are

binding by turning the front fork all the way in

properly tightened.

both directions. If any binding is felt, remove

Refer to “CHASSIS TIGHTENING TORQUES”

the lower bracket and check the upper and

on page 2-16.

lower bearings.

EAS21700

Refer to

“CHECKING THE STEERING

LUBRICATING THE LEVERS

HEAD” on page 4-46.

Lubricate the pivoting point and metal-to-metal

e. Install the rubber washer “1”.

moving parts of the levers.

f. Install the upper ring nut “2”.

3-19

PERIODIC MAINTENANCE

no danger of it falling over.

Recommended brake lever lubri-

cant

2. Check:

Silicone grease

• Inner tube

Recommended clutch lever lubri-

Damage/scratches Replace.

cant

• Front fork leg

Lithium-soap-based grease

Oil leaks between inner tube and outer tube

Replace the oil seal.

EAS21710

3. Hold the vehicle upright and apply the front

LUBRICATING THE PEDAL

brake.

Lubricate the pivoting point and metal-to-metal

4. Check:

moving parts of the pedal.

• Front fork operation

Recommended lubricant

Push down hard on the handlebar several

Lithium-soap-based grease

times and check if the front fork rebounds

smoothly.

EAS2RD1026

Rough movement Repair.

CHECKING THE SIDESTAND

Refer to “FRONT FORK” on page 4-37.

1. Check:

• Sidestand operation

Check that the sidestand moves smoothly.

Rough movement Repair or replace.

EAS21720

LUBRICATING THE SIDESTAND

Lubricate the pivoting point, metal-to-metal mov-

ing parts and spring contact point of the sides-

tand.

Recommended lubricant

EAS2RD1036

Lithium-soap-based grease

CHECKING THE REAR SHOCK ABSORBER

EAS2RD1038

ASSEMBLY

CHECKING THE CENTERSTAND

Refer to “CHECKING THE REAR SHOCK AB-

1. Check:

SORBER ASSEMBLY” on page 4-49.

• Centerstand operation

EAS21590

Check that the centerstand moves smoothly.

ADJUSTING THE REAR SHOCK ABSORBER

Rough movement Repair or replace.

ASSEMBLY

EWA13120

EAS21730

WARNING

LUBRICATING THE CENTERSTAND

Lubricate the pivoting point and metal-to-metal

Securely support the vehicle so that there is

moving parts of the centerstand.

no danger of it falling over.

Spring preload

Recommended lubricant

ECA13590

Lithium-soap-based grease

NOTICE

EAS2RD1033

Never go beyond the maximum or minimum

CHECKING THE SIDESTAND SWITCH

adjustment positions.

Refer to “ELECTRICAL COMPONENTS” on

1. Adjust:

page 7-49.

• Spring preload

EAS21531

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

CHECKING THE FRONT FORK

a. Turn the adjusting ring “1” in direction “a” or

1. Stand the vehicle on a level surface.

“b”.

EWA13120

b. Align the desired position on the adjusting

WARNING

ring with the stopper “2”.

Securely support the vehicle so that there is

3-20

PERIODIC MAINTENANCE

Direction “a”

Spring preload is increased (suspen-

sion is harder).

Direction “b”

Spring preload is decreased (suspen-

sion is softer).

b

Spring preload adjusting positions

a

Minimum

1

Standard

1

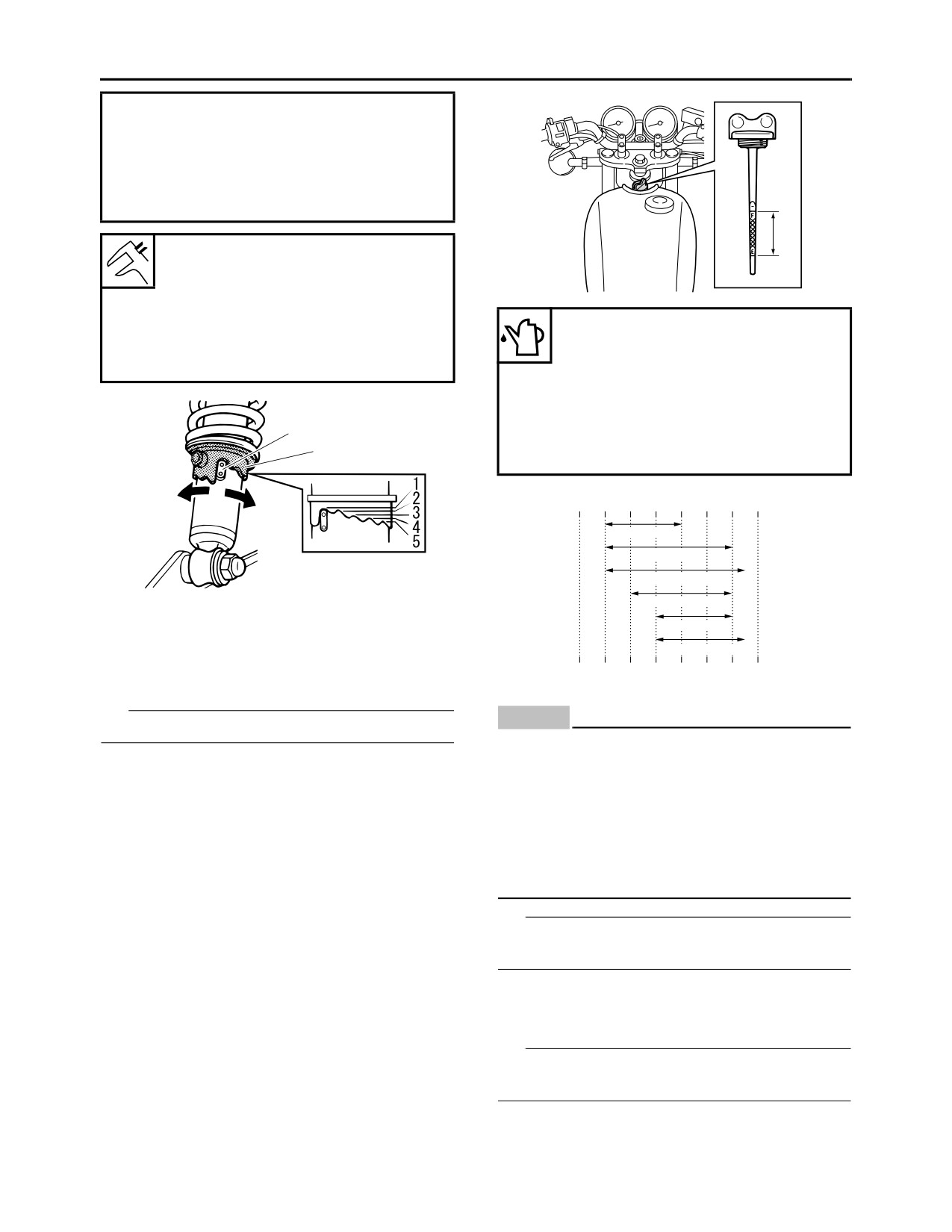

Recommended brand

Maximum

YAMALUBE

5

Type

SAE 10W-30, 10W-40, 10W-50,

15W-40, 20W-40 or 20W-50

Recommended engine oil grade

2

API service SG type or higher,

1

JASO standard MA

a

b

0

10

30

50

70

90 110130 °F

SAE 10W-30

SAE 10W-40

SAE 10W-50

SAE 15W-40

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

SAE 20W-40

EAS20731

SAE 20W-50

CHECKING THE ENGINE OIL LEVEL

-20 -10

0

10

20

30

40

50 °C

1. Stand the vehicle on a level surface.

ECA13361

TIP

NOTICE

Place the vehicle upright on the centerstand.

• Engine oil also lubricates the clutch and the

2. Start the engine, warm it up for several min-

wrong oil types or additives could cause

utes, and then turn it off. Before checking the

clutch slippage. Therefore, do not add any

engine oil level, wait a few minutes until the oil

chemical additives or use engine oils with a

has settled.

grade of “CD” or higher and do not use oils

3. Check:

labeled “ENERGY CONSERVING II”.

• Engine oil level

• Do not allow foreign materials to enter the

The engine oil level should be between the

crankcase.

minimum level mark “a” and maximum level

TIP

mark “b”.

Before checking the engine oil level, wait a few

Below the minimum level mark Add the

minutes until the oil has settled.

recommended engine oil to the proper level.

4. Start the engine, warm it up for several min-

utes, and then turn it off.

5. Check the engine oil level again.

TIP

Before checking the engine oil level, wait a few

minutes until the oil has settled.

EAS20811

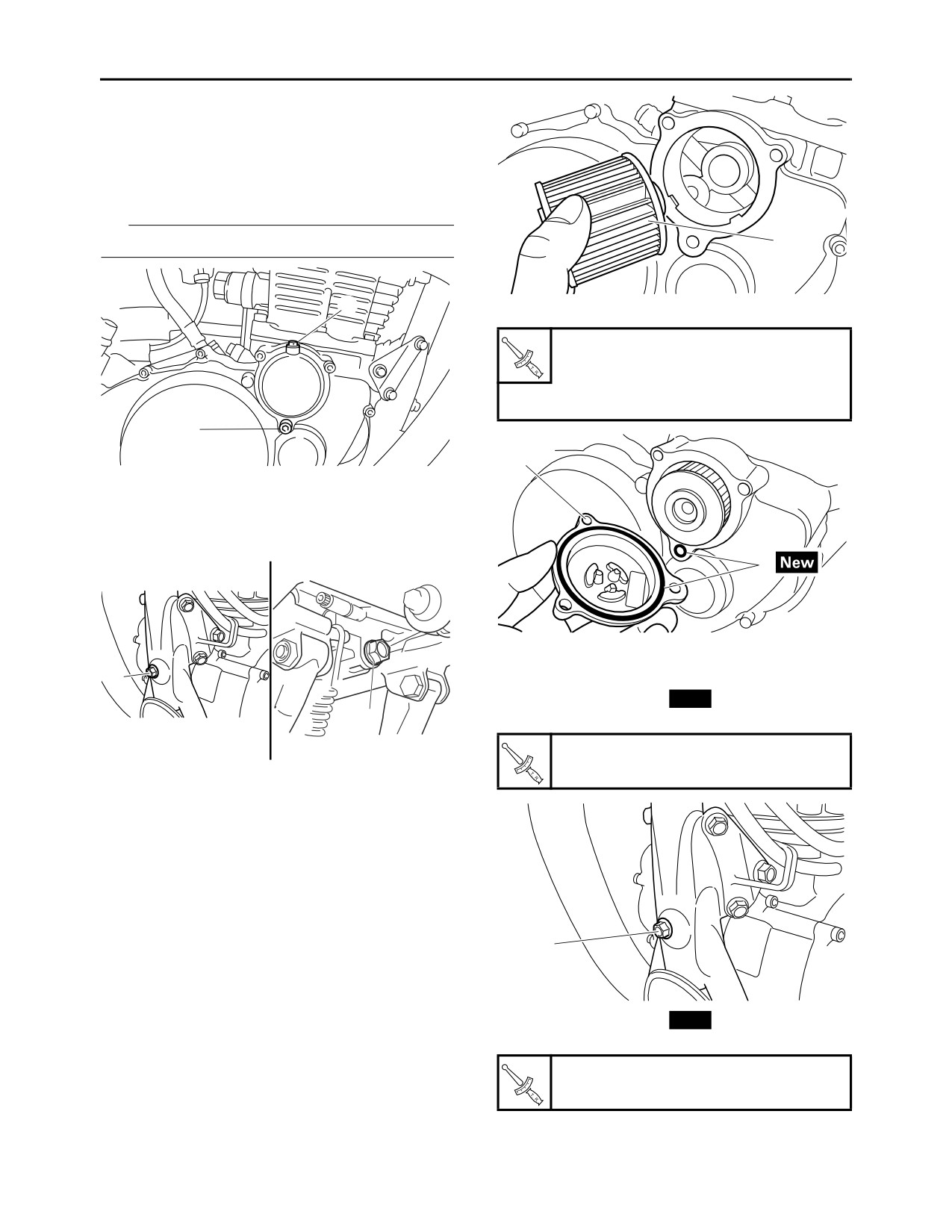

CHANGING THE ENGINE OIL

1. Start the engine, warm it up for several min-

3-21

PERIODIC MAINTENANCE

utes, and then turn it off.

2. Place a container under the engine oil drain

bolt.

3. Loosen:

• Bleeder bolt “1”

• Oil filter cover bolt “2”

TIP

Do not remove the bolt.

1

1

c. Install a new O-ring “2” and oil filter cover “3”.

Oil filter cover bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Bleeder bolt

5 Nm (0.5 m·kgf, 3.6 ft·lbf)

2

3

4. Remove:

• Engine oil level gauge

• Oil drain bolt (oil tank side) “1”

• Oil drain bolt (crankcase side) “2”

2

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

1

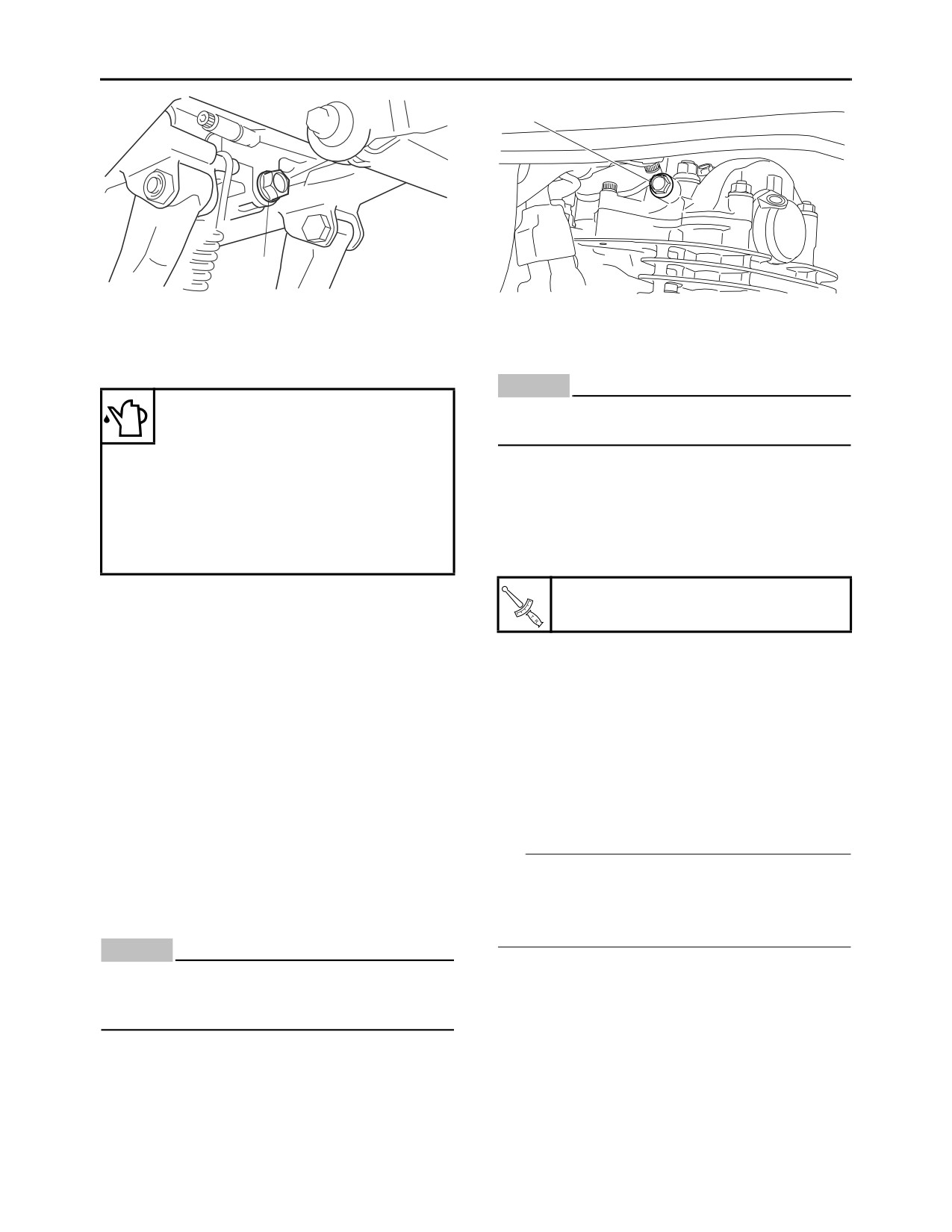

7. Install:

• Oil drain bolt gasket

New

2

• Oil drain bolt (oil tank side) “1”

Oil drain bolt

16 Nm (1.6 m·kgf, 12 ft·lbf)

5. Drain:

• Engine oil

(completely from the oil tank and the crank-

case)

6. If the oil filter element is also to be replaced,

perform the following procedure.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the oil filter cover and oil filter ele-

ment.

1

b. Install a new oil filter element “1”.

• Oil drain bolt gasket

New

• Oil drain bolt (crankcase side) “2”

Oil drain bolt

30 Nm (3.0 m·kgf, 22 ft·lbf)

3-22

PERIODIC MAINTENANCE

1

2

8. Fill:

b. Start the engine and check to see if oil seeps

• Oil tank

out while idling the engine for about one min-

(with the specified amount of the recom-

ute.

ECA2RD1003

mended engine oil)

NOTICE

Engine oil quantity

Any inspection must be conducted at engine

Quantity (disassembled)

idling speed. Do not rev up the engine.

2.40 L (2.54 US qt, 2.11 Imp.qt)

Without oil filter element replace-

c. If no oil seeps out, check the engine oil pas-

ment

sages, the oil filter element and the oil pump

2.00 L (2.11 US qt, 1.76 Imp.qt)

for damage or leakage.

With oil filter element replace-

d. Start the engine after solving the problem(s)

ment

and make sure that oil seeps out.

2.10 L (2.22 US qt, 1.85 Imp.qt)

e. Tighten the oil check bolt to specification.

9. Install:

Oil check bolt

• Engine oil level gauge

18 Nm (1.8 m·kgf, 13 ft·lbf)

10.Start the engine, warm it up for several min-

utes, and then turn it off. Before checking the

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

engine oil level, wait a few minutes until the oil

EAS2RD1037

has settled.

CHECKING THE FRONT BRAKE LIGHT

11.Check:

SWITCH

• Engine

Refer to “ELECTRICAL COMPONENTS” on

(for engine oil leaks)

page 7-49.

12.Check:

• Engine oil level

EAS21330

ADJUSTING THE REAR BRAKE LIGHT

Refer to “CHECKING THE ENGINE OIL

SWITCH

LEVEL” on page 3-21.

13.Check:

TIP

The rear brake light switch is operated by move-

• Engine oil pressure

ment of the brake pedal. The rear brake light

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

switch is properly adjusted when the brake light

a. Slightly loosen the oil check bolt “1”.

ECA2RD1002

comes on just before the braking effect starts.

NOTICE

1. Check:

Engine start-up with the oil check bolt re-

• Rear brake light operation timing

moved will cause an oil spout. Check with

Incorrect Adjust.

the oil check bolt loosened without fail.

2. Adjust:

• Rear brake light operation timing

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Hold the main body “1” of the rear brake light

switch so that it does not rotate and turn the

adjusting nut “2” in direction “a” or “b” until the

rear brake light comes on at proper timing.

3-23

PERIODIC MAINTENANCE

Rough movement Lubricate or replace the

Direction “a”

defective part(s).

Brake light comes on sooner.

Direction “b”

Recommended lubricant

Brake light comes on later.

Suitable cable lubricant

TIP

With the engine stopped, turn the throttle grip

a

1

slowly and release it. Make sure that the throttle

grip turns smoothly and returns properly when

b

released.

2

Repeat this check with the handlebar turned all

the way to the left and right.

3. Check:

• Throttle grip free play “a”

Out of specification Adjust.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Throttle grip free play

EAS21690

3.0-5.0 mm (0.12-0.20 in)

CHECKING AND LUBRICATING THE

CABLES

The following procedure applies to all of the in-

ner and outer cables.

EWA13270

a

WARNING

Damaged outer cable may cause the cable to

corrode and interfere with its movement. Re-

place damaged outer cable and inner cables

as soon as possible.

1. Check:

• Outer cable

4. Adjust:

Damage Replace.

• Throttle grip free play

2. Check:

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

• Cable operation

Throttle body side

Rough movement Lubricate.

a. Loosen the locknut “1” on the decelerator ca-

Recommended lubricant

ble.

Suitable cable lubricant

b. Turn the adjusting nut “2” in direction “a” or “b”

to take up any slack on the decelerator cable.

TIP

c. Loosen the locknut “3” on the accelerator ca-

Hold the cable end upright and pour a few drops

ble.

of lubricant into the cable sheath or use a suit-

d. Turn the adjusting nut “4” in direction “a” or “b”

able lubricating device.

until the specified throttle grip free play is ob-

tained.

EAS30890

CHECKING THE THROTTLE GRIP

Direction “a”

1. Check:

Throttle grip free play is increased.

• Throttle cable

Direction “b”

Throttle grip free play is decreased.

Damage/deterioration Replace.

• Throttle cable installation

e. Tighten the locknuts “1” and “3”.

Incorrect Reinstall the throttle cables.

Refer to “HANDLEBAR” on page 4-33.

2. Check:

• Throttle grip movement

3-24

PERIODIC MAINTENANCE

EAS21770

b

CHECKING THE FUSES

a

a

4

Refer to “CHECKING THE FUSES” on page

b

7-57.

2

3

EAS21790

1

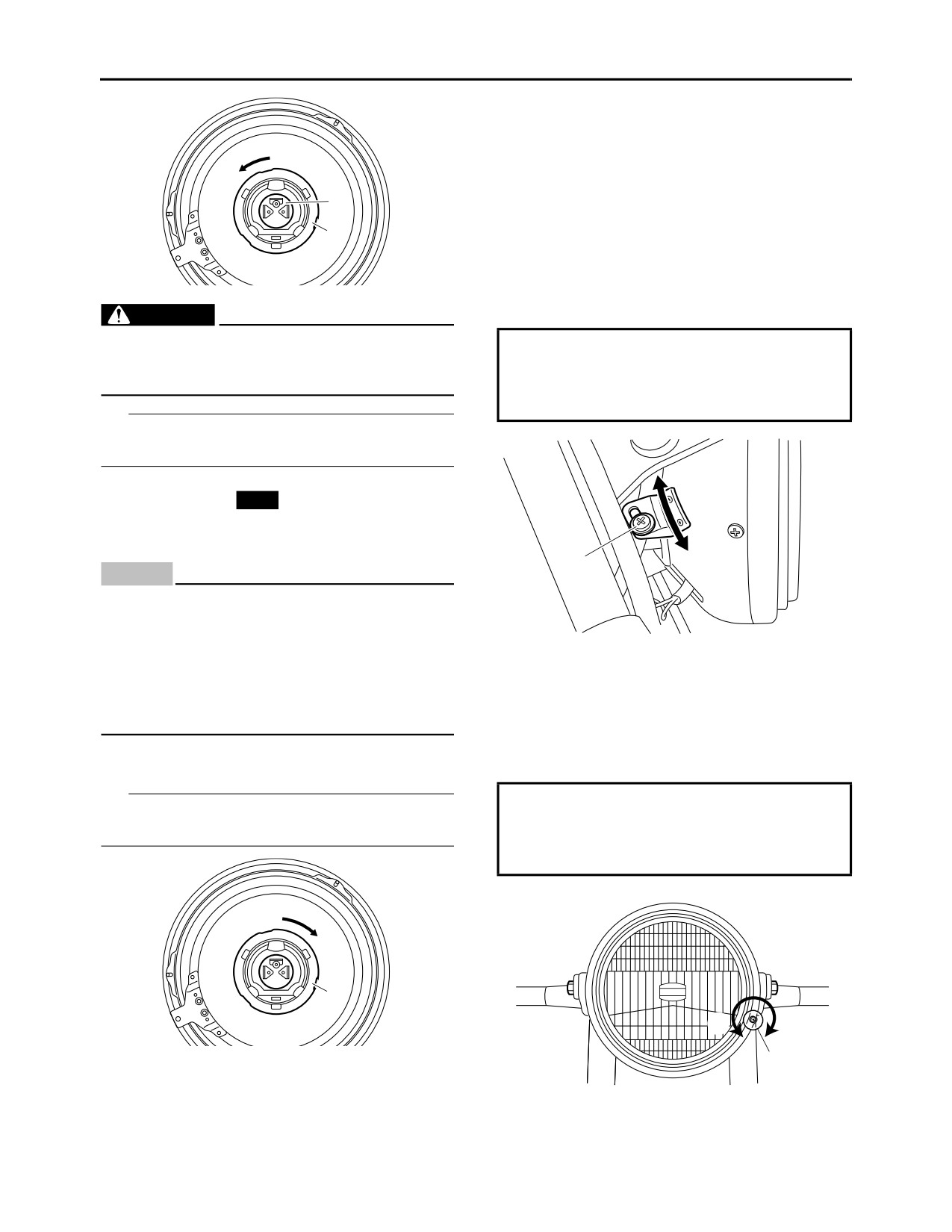

REPLACING THE HEADLIGHT BULB

1. Remove:

•S

crew “1”

•H

eadlight

unit a

ssembly “2”

TIP

If the specified throttle grip free play cannot be

obtained on the throttle body side of the cable,

use the adjusting nut on the handlebar side.

2

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

1

Handlebar side

a. Loosen the locknut “1”.

b. Turn the adjusting nut “2” in direction “a” or “b”

until the specified throttle grip free play is ob-

tained.

Direction “a”

Throttle grip free play is increased.

2

Direction “b”

Throttle grip free play is decreased.

1

c. Tighten the locknut.

2. Disconnect:

1

• Headlight coupler “1”

3. Remove:

• Headlight bulb cover “2”

2

1

2

a

b

EWA2RD1001

WARNING

After adjusting the throttle grip free play,

start the engine and turn the handlebars to

the right and to the left to ensure that this

4. Remove:

does not cause the engine idling speed to

• Headlight bulb holder “1”

change.

• Headlight bulb “2”

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS21760

CHECKING AND CHARGING THE BATTERY

Refer to “CHECKING AND CHARGING THE

BATTERY” on page 7-58.

3-25

PERIODIC MAINTENANCE

9. Install:

• Headlight unit assembly

• Screw

EAS21800

ADJUSTING THE HEADLIGHT BEAM

2

1. Adjust:

1

• Headlight beam (vertically)

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the adjusting screw “1” and move the

headlight unit in direction “a” or “b” for adjust-

EWA13320

ment.

WARNING

Since the headlight bulb gets extremely hot,

Direction “a”

keep flammable products and your hands

Headlight beam is raised.

away from the bulb until it has cooled down.

Direction “b”

Headlight beam is lowered.

TIP

Remove the headlight bulb holder by turning it

counterclockwise.

b

5. Install:

• Headlight bulb

New

Secure the new headlight bulb with the head-

light bulb holder.

a

ECA13690

1

NOTICE

Avoid touching the glass part of the head-

light bulb to keep it free from oil, otherwise

the transparency of the glass, the life of the

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

bulb and the luminous flux will be adversely

affected. If the headlight bulb gets soiled,

2. Adjust:

thoroughly clean it with a cloth moistened

• Headlight beam (horizontally)

with alcohol or lacquer thinner.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the adjusting screw “1” in direction “a” or

6. Install:

“b” for adjustment.

• Headlight bulb holder “1”

TIP

Direction “a”

Install the headlight bulb holder by turning it

Headlight beam moves to the right.

clockwise.

Direction “b”

Headlight beam moves to the left.

1

b

a

7. Install:

1

• Headlight bulb cover

8. Connect:

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

• Headlight coupler

3-26